2021 may day cup mathematical modeling problem A

Vaccine production issues

The novel coronavirus pneumonia has been a worldwide disaster and has brought serious disasters to the world. Countries have developed new vaccines to control the epidemic. It is assumed that vaccine production needs to go through four process flows: CJ1 station, CJ2 station, CJ3 station and CJ4 station. Each process flow can process 100 doses of vaccine at one time. The 100 doses of vaccine are loaded into a processing box and sent to the equipment at the station for treatment. Moreover, the production can be completed only after the four stations are processed in the order of CJ1-CJ2-CJ3-CJ4. In order to prevent confusion in vaccine packaging, the production department of a vaccine production company stipulates that each station cannot produce different types of vaccines at the same time, and it is not allowed to jump the queue in vaccine production, that is, once the production sequence of each type of vaccine arranged in the first station is determined, it will remain unchanged, and after the former type of vaccine leaves a station, The latter type of vaccine can enter this station.

At present, 10 different types of vaccines such as YM1-YM10 need to be produced. For the sake of safety, each type of vaccine in each box (containing 100 doses of vaccine) has been simulated for 50 times at each station. It is found that the time required for each station to produce different types of vaccine in each box is not stable due to various reasons such as production equipment and vaccine purification. See Annex 1 for detailed data.

Please build a mathematical model and answer the following questions:

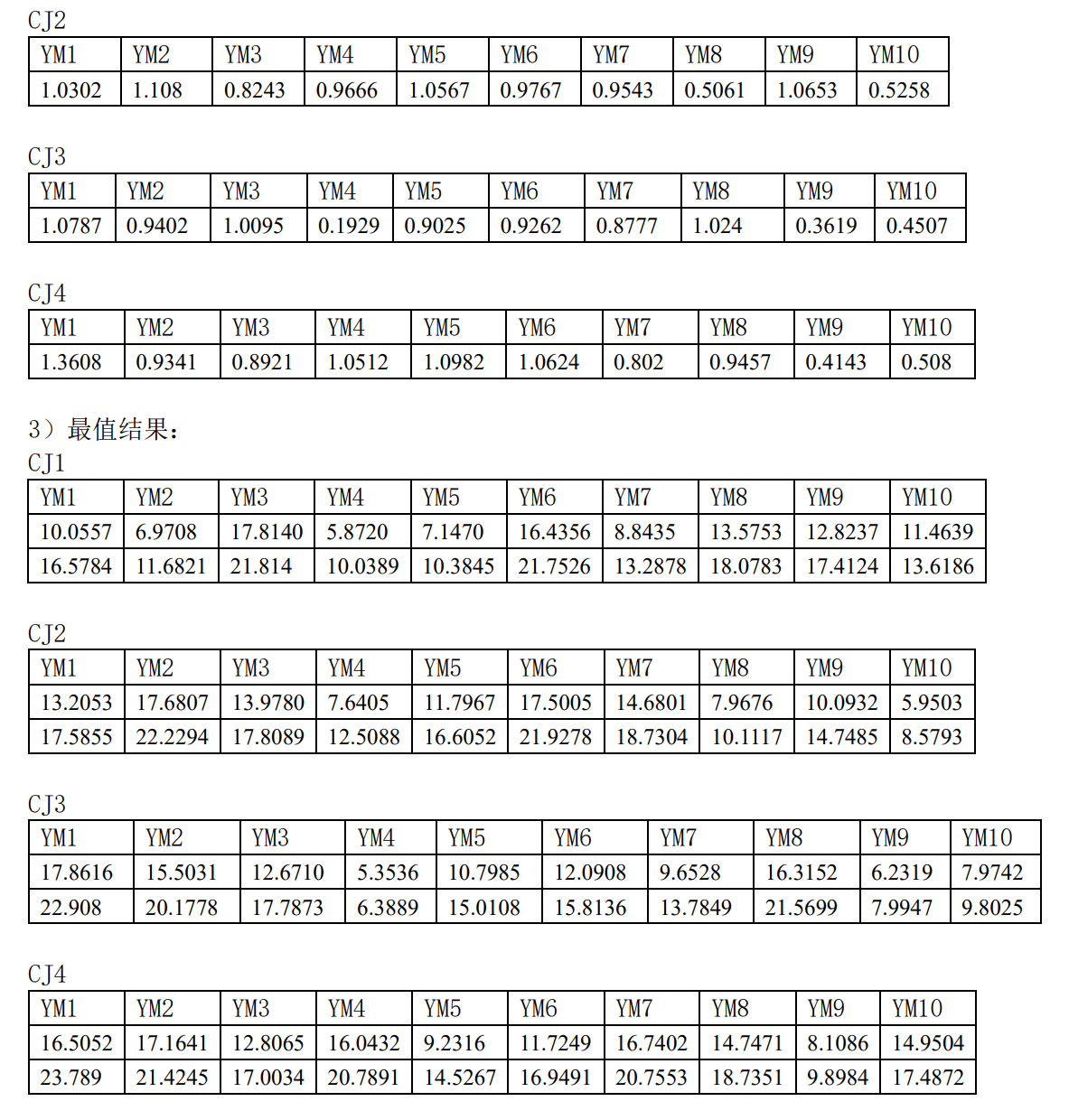

Question 1: please conduct statistical analysis on the production time of each box of vaccine at all stations, such as mean value, variance, maximum value and probability distribution, so that the managers of vaccine production companies can intuitively grasp the ability level of vaccine production at each station and provide reference for vaccine production.

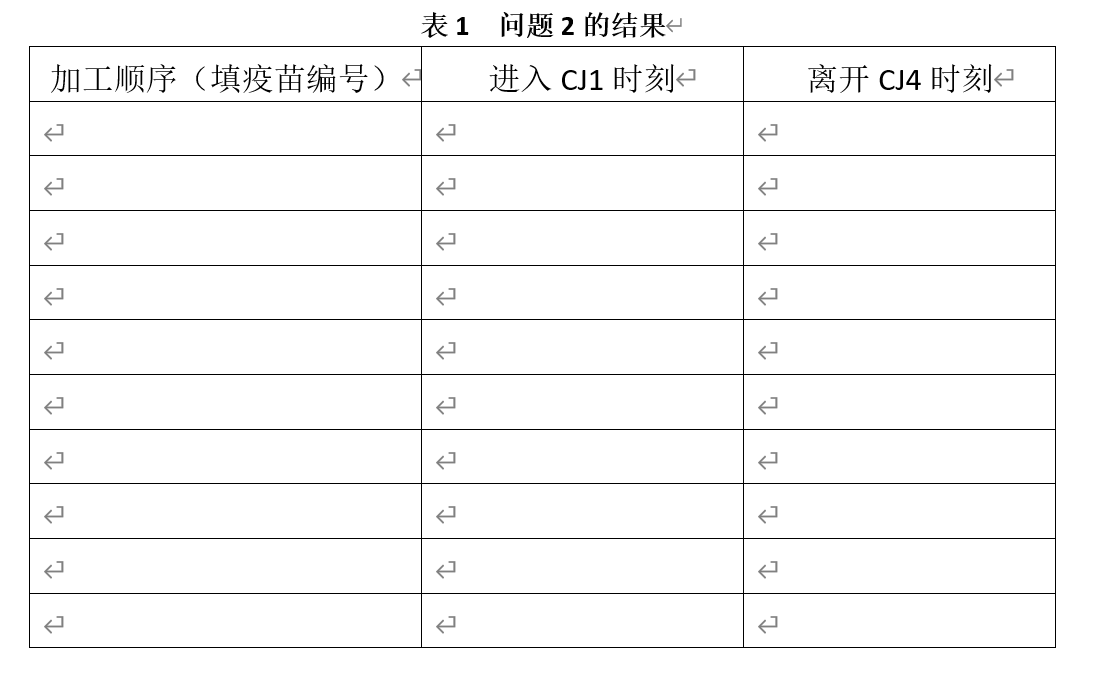

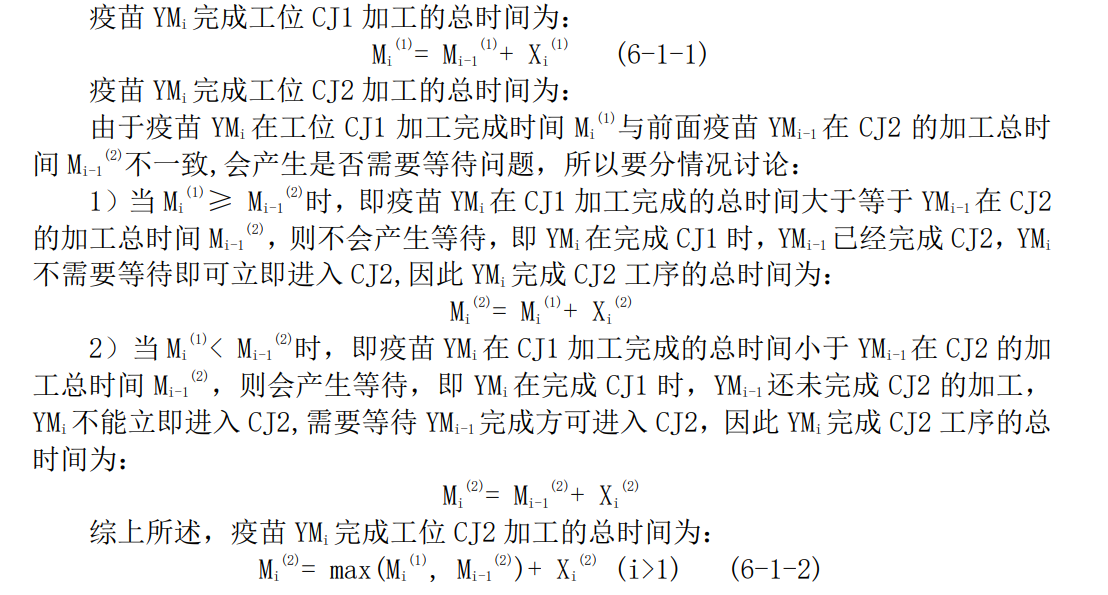

Question 2: the vaccine testing department of a country urgently needs 100 doses of YM1-YM10 vaccine for testing. In order to be in a hurry, the vaccine production company needs to plan the production sequence of the vaccine so that it can be delivered in the shortest time, based on the average time of producing each box of vaccine at each station. Please establish a mathematical model, formulate the vaccine production sequence, the initial time is 00:00, calculate the total production time, and fill the results in Table 1.

Question 3: in actual production, the time required for each vaccine in each station is random. If the company is required to shorten the total vaccine delivery time by 5% compared with the total time in question 2, please establish a mathematical model, take the maximum probability to complete this task as the goal, determine the production sequence, and give the relationship between the shortened time proportion and the maximum probability.

Question 4: now the vaccine production company has received production tasks of 10 types of vaccines of different scales (see Annex 2). Since the production machines need to be overhauled and maintained, the daily production time of each station can not exceed 16 hours. In order to avoid wrong packaging of vaccines, the production task of each type of vaccine can not be separated, that is, another type of vaccine can be produced only after the production of the same type of vaccine is completed. Please establish a mathematical model and arrange production on the premise of 90% reliability Production plan, at least how many days can you complete the task?

Question 5: if the vaccine production company plans to select part of the vaccine for production within 100 days, the daily production time of each station can not exceed 16 hours. The production task of each type of vaccine can be divided appropriately, that is, only part of each type of vaccine can be completed. With the maximum sales as the goal, please establish a mathematical model to arrange the production plan.

Model establishment and solution (part) (see the comment area for all documents and procedures)

Establishment and solution of the first mock exam model:

Problem two: establishment and solution of the model:

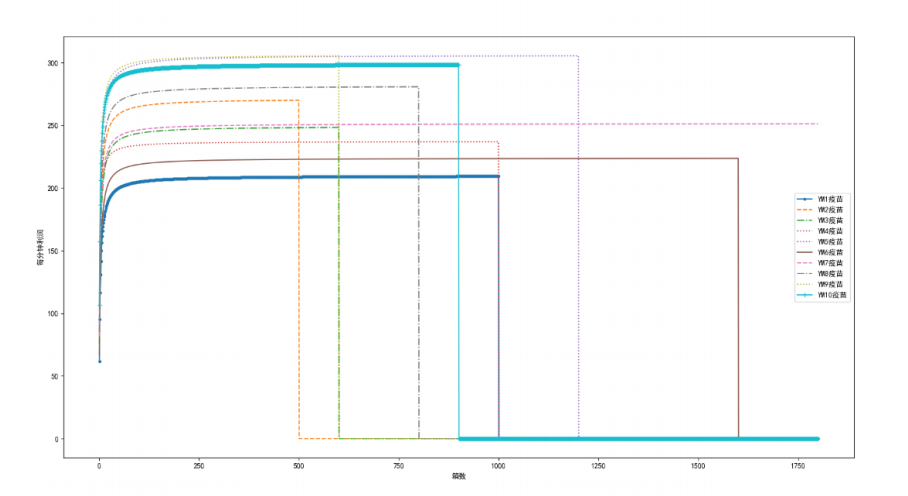

Problem three: establishment and solution of the model:

According to the first question, the probability distribution of vaccine on each production line belongs to normal distribution. In other words, in the above formula, we can regard it as the deviation coefficient τ It conforms to normal distribution. Then, the random production time of vaccine can be simulated by using Matlab to generate random values of normal distribution. In the second question, we use Matlab to traverse all cases to test the results. In this question, we can use the code of the second question to add conditions according to the meaning of the question. Repeated calculation α Times, calculate the final time T of each time through the method of the second problem, and count the times in which the final time T is less than 95% of the minimum time β, Then the approximate probability P of the scheme can be obtained= β/α

Establishment and solution of problem 4 and problem 5 models:

The program code is as follows:

A=[13.284 9.8708 20.0584 7.9886 8.77 19.0741 11.1601 16.0201 15.0146 12.9524

14.9621 19.9075 15.9726 9.9366 13.722 20.0943 16.4961 8.8274 12.0351

7.0109

19.846 17.9281 14.9703 5.9358 13.0052 14.1485 12.0136 18.1143 7.0419

9.0491

20.0129 18.9423 15.1163 18.1283 11.2494 13.8838 19.0876 16.8313 8.9496

16.0524

];

Y=[1.593979267 0.793439961 0.809040273 0.999774981 0.613356028 1.315886921 1.032082042 1.229791443 0.991973399 0.20800367

1.051043473 1.121878635 0.648764524 0.988125675 1.15461187

0.876216121 0.901073535 0.226411679 1.220333417 0.294923796

1.222915487 0.899972852 1.082819843 0.039376599 0.866617616

0.914373457 0.694742886 1.134968066 0.130686652 0.196699049

1.849122356 0.898665829 0.858227975 1.138880455 1.279170491

1.227569715 0.685524548 0.97057379 0.181558835 0.260809703];

x=[]; baogao=0;

maxgailv100=[]; maxgailv95=[];maxgailv90=[];maxgailv85=[];maxgailv80=[];maxgailv75=[

];maxgailv70=[];maxgailv65=[];maxgailv60=[]; maxgailv55=[];maxgailv50=[];

T100=191.7157;

T95=191.7157*0.95; T90=191.7157*0.90; T85=191.7157*0.85;

T80=191.7157*0.80; T75=191.7157*0.75; T70=191.7157*0.70; T65=191.7157*0.65; T60=191.7157*0.60; T55=191.7157*0.55; T50=191.7157*0.50;

aa=perms(1:10); b=1814400;

for j=1:1814400

a(j,:)=aa(ZI(1,j),:);

end

for c=1:b

count100=0;

count95=0;

count90=0;

count85=0;

count80=0;

count75=0;

count70=0;

count65=0;

count60=0;

count55=0;

count50=0;

baogao=baogao+1

for i=1:500

q=normrnd(0,1,1,1);

x=A+Y*q;

x1=a(c,:);

T1=x(1,a(c,1));

T2=x(2,a(c,1))+x(1,a(c,1));

T3=T2+x(3,a(c,1));

T4=T3+x(4,a(c,1));

for d=2:10

for e=1:4

if e==1

T1=T1+x(1,a(c,d));

end

if e==2

T2a=T2+x(2,a(c,d));

T2b=T1+x(2,a(c,d));

if T2a>=T2b

T2=T2a;

else

T2=T2b;

end

end

if e==3

T3a=T3+x(3,a(c,d));

T3b=T2+x(3,a(c,d));

if T3a>=T3b

T3=T3a;

else

T3=T3b;

end

end

if e==4

T4a=T4+x(4,a(c,d));

T4b=T3+x(3,a(c,d));

if T4a>=T4b

T4=T4a;

else

T4=T4b;

end

end

end

end

if T4<=T100

count100=count100+1;

end

if T4<=T95

count95=count95+1;

end

if T4<=T90

count90=count90+1;

end

if T4<=T85

count85=count85+1;

end

if T4<=T80

count80=count80+1;

end

if T4<=T75

count75=count75+1;

end

if T4<=T70

count70=count70+1;

end

if T4<=T65

count65=count65+1;

end

if T4<=T60

count60=count60+1;

end

if T4<=T55

count55=count55+1;

end

if T4<=T50

count50=count50+1;

end

end

h100=count100/500;

maxgailv100(1,c)=h100;

h95=count95/500;

maxgailv95(1,c)=h95;

h90=count90/500;

maxgailv90(1,c)=h90;

h85=count85/500;

maxgailv85(1,c)=h85;

h80=count80/500;

maxgailv80(1,c)=h80;

h75=count75/500;

maxgailv75(1,c)=h75;

h70=count70/500;

maxgailv70(1,c)=h70;

h65=count65/500;

maxgailv65(1,c)=h65;

h60=count60/500;

maxgailv60(1,c)=h60;

h55=count55/500;

maxgailv55(1,c)=h55;

h50=count50/500;

maxgailv50(1,c)=h50;

end

MAX100=max(maxgailv100) MAX95=max(maxgailv95) MAX90=max(maxgailv90) MAX85=max(maxgailv85) MAX80=max(maxgailv80) MAX75=max(maxgailv75) MAX70=max(maxgailv70) MAX65=max(maxgailv65) MAX60=max(maxgailv60) MAX55=max(maxgailv55) MAX50=max(maxgailv50)

Answer documents and procedures for this topic:

print("qq: 917267119")