Rotational softening and stress stiffening

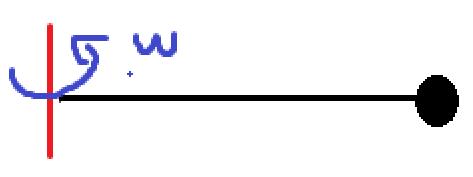

Plate rotation

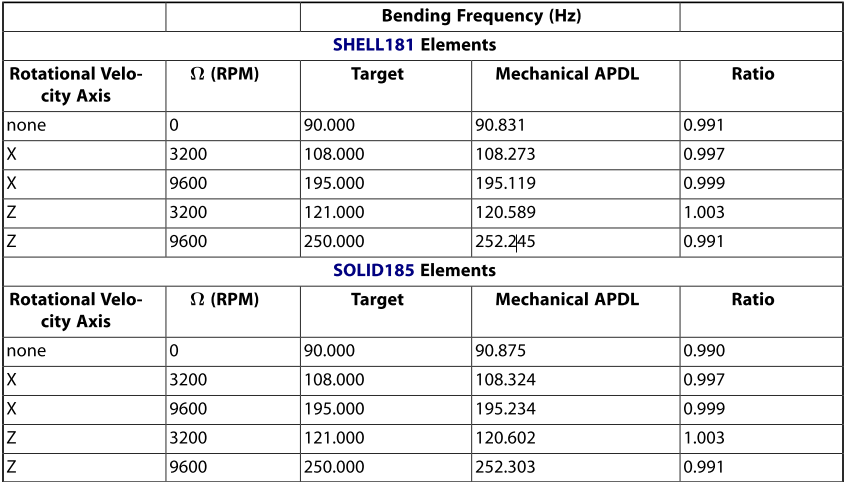

Two units: shell181 and solid185. Analyze five situations: static, 3200rpm around the x axis at y=-0.1, 9600rpm around the x axis at y=-0.1, 3200rpm around the z axis at y=-0.1, and 9600rpm around the z axis at y=-0.1.

Only the first-order modal frequency is extracted, so 10 results are obtained.

The verification manual points out that when the plate rotates around the x-axis, both stress stiffening and rotation softening affect the bending mode; When rotating around the z-axis, the influence of rotation softening on the bending mode can be ignored.

The stress stiffening and rotation softening here are caused by the centrifugal force during rotation. First carry out nonlinear static analysis, and then linear pertubation modal analysis. The block Lanczos eigensolver is used to calculate the eigenvalues.

for instance:

A rod has elasticity but no mass, and a mass ball at one end rotates around an axis. The centrifugal force will lengthen the rod and increase the centrifugal force, which is rotation softening; However, the axial force of the rod increases the transverse stiffness and the transverse bending modal frequency, which is stress stiffness.

SHELL181 is suitable for analyzing thin and medium thickness plate and shell structural parts. It has four nodes in a unit, and each node has six degrees of freedom, that is, moving degrees of freedom and rotating degrees of freedom along the X, Y and Z directions. (if the film option is selected, the unit can only use degrees of freedom of movement). The degenerate triangle option can only be used in filtering unitized grids.

SHELL181 supports linear, large torsion and large strain, variable thickness nonlinear analysis. It can be used in both complete method and reduction method, and can be used for distributed load and stress stiffening.

SHELL181 can be used for multilayer material models. The accuracy of plate and shell modeling is determined by Mindlin Reissner shell theory.

In case of convergence difficulties, SHELL181 is used to replace SHELL43 unit. For details of this unit, please refer to ANSYS, In

solid185 unit has 8 nodes, and each node has three degrees of freedom. Therefore, compared with the upper and lower figures, the node degrees of freedom at y=0 are constrained, but the yellow part in the above figure is the rotation degrees of freedom.

code

Due to the * VWRITE command, it can only be run in batch

/clear /COM,ANSYS MEDIA REL. 150 (11/8/2013) REF. VERIF. MANUAL: REL. 150 /VERIFY,VM281 /TITLE,VM281,EFFECT OF STRESS STIFFENING AND SPIN SOFTENING ON A ROTATING PLATE /COM, /COM, REFERENCE: NASA TECHNICAL MEMORANDUM 89861,PAGE 14,FIGURE 7 /COM, /COM, ===================================================================== /COM, MODELING THE PLATE USING 4-NODE STRUCTURAL SHELL ELEMENT (SHELL181) /COM, ====================================================================== /PREP7 lg = 152.4e-3 ! LENGTH IN METERS wd = 50.8e-3 ! WIDTH IN METERS tk = 2.54e-3 ! THICKNESS IN METERS K,1,-wd/2,0,0 ! Defines a keypoint. K,2,+wd/2,0,0 K,3,+wd/2,lg,0 K,4,-wd/2,lg,0 A,1,2,3,4 ! Defines an area by connecting keypoints. /COM, MATERIAL PROPERTIES OF STRUCTURAL STEEL PLATE MP,EX,1,2.0e+11 ! 1 Modulus of elasticity of material No MP,DENS,1,7850 ! 1 Density of material No MP,NUXY,1,0.3 ! 1 Poisson's ratio of material No ET,1,SHELL181 ! 4-NODE STRUCTURAL SHELL ELEMENT SECTYPE,1,SHELL ! Defining shell element sections SECDATA,tk,1,10,3 ! THICKNESS Angle integral point of thickness layer coordinate system relative to element coordinate system TYPE,1 !Set current cell MAT,1 !Set current material SECNUM,1 !Sets the current section ESIZE,5e-3 !Length of division unit AMESH,1 !Dividing surface element NSEL,S,LOC,Y,0.0 !Select y=0 All nodes of D,ALL,ALL ! CONSTRAINING ALL DOF AT BASE ALLSEL,ALL CM,PLATE,ELEM ! FORMING A COMPONENT WITH ALL ELEMENTS SAVE,SHELL,DB ! SAVE THE DATABASE FINISH /COM, ---------------------- /COM, NO ROTATION static /COM, ---------------------- /OUT,SCRATCH /SOLUTION ANTYPE,MODAL ! modal analysis MODOPT,LANB,4 ! EXTRACT 4 MODES USING BLOCK-LANCZOS MXPAND,4 !http://blog.sina.com.cn/s/blog_9b0ec2070102z2mu.html SOLVE /OUT, *GET,FREQ1_SH,MODE,1,FREQ ! *GET Solution Items, Entity = MODE Extract the first-order modal frequency and assign it to FREQ1_SH FINISH /DELETE,,rst ! delete rst file /COM, -------------------------------------- /COM, PLATE ROTATED ALONG X AXIS AT 3200 RPM Round x Shaft 3200 rpm The prestress generated by centrifugal force is added to the modal analysis /COM, -------------------------------------- /OUT,SCRATCH ! /OUTPUT of Notes /SOLUTION ANTYPE,STATIC ! static analysis OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,3200*pi/30,,,0,OFFSET,0,1,OFFSET,0 ! ROTATING THE PLATE ALONG X AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 ! The load step time is 1 AUTOTS,ON ! Automatic load step NSUBS,10,100,1 ! Sub step: 10 steps, minimum 1 step, maximum 100 steps OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS Prestressed modal analysis PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX Regenerate cell matrix MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ2_SH,MODE,1,FREQ ! *GET Solution Items, Entity = MODE Extract the first-order modal frequency and assign it to FREQ2_SH FINISH /DELETE,,rst /DELETE,,rstp /COM, -------------------------------------- /COM, PLATE ROTATED ALONG X AXIS AT 9600 RPM /COM, -------------------------------------- /OUT,SCRATCH /SOLUTION ANTYPE,STATIC OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,9600*pi/30,,,0,OFFSET,0,1,OFFSET,0 ! ROTATING THE PLATE ALONG X AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 AUTOTS,ON NSUBS,10,100,1 OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ3_SH,MODE,1,FREQ ! *GET Solution Items, Entity = MODE Extract the first-order modal frequency and assign it to FREQ3_SH FINISH /DELETE,,rst /DELETE,,rstp /COM, -------------------------------------- /COM, PLATE ROTATED ALONG Z AXIS AT 3200 RPM /COM, -------------------------------------- /OUT,SCRATCH /SOLUTION ANTYPE,STATIC OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,3200*pi/30,,,0,OFFSET,0,0,OFFSET,1 ! ROTATING THE PLATE ALONG Z AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 AUTOTS,ON NSUBS,10,100,1 OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ4_SH,MODE,1,FREQ FINISH /DELETE,,rst /DELETE,,rstp /COM, -------------------------------------- /COM, PLATE ROTATED ALONG Z AXIS AT 9600 RPM /COM, -------------------------------------- /OUT,SCRATCH /SOLUTION ANTYPE,STATIC OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,9600*pi/30,,,0,OFFSET,0,0,OFFSET,1 ! ROTATING THE PLATE ALONG Z AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 AUTOTS,ON NSUBS,10,100,1 OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ5_SH,MODE,1,FREQ FINISH /OUT,SCRATCH *DIM,LABEL,CHAR,5,2 *DIM,VALUE,,5,3 LABEL(1,1) = 'None' LABEL(1,2) = '0rpm' LABEL(2,1) = 'X axis' LABEL(2,2) = '3200rpm' LABEL(3,1) = 'X axis' LABEL(3,2) = '9600rpm' LABEL(4,1) = 'Z axis' LABEL(4,2) = '3200rpm' LABEL(5,1) = 'Z axis' LABEL(5,2) = '9600rpm' *VFILL,VALUE(1,1),DATA,90 *VFILL,VALUE(1,2),DATA,FREQ1_SH *VFILL,VALUE(1,3),DATA,(90/FREQ1_SH) *VFILL,VALUE(2,1),DATA,108 *VFILL,VALUE(2,2),DATA,FREQ2_SH *VFILL,VALUE(2,3),DATA,(108/FREQ2_SH) *VFILL,VALUE(3,1),DATA,195 *VFILL,VALUE(3,2),DATA,FREQ3_SH *VFILL,VALUE(3,3),DATA,(195/FREQ3_SH) *VFILL,VALUE(4,1),DATA,121 *VFILL,VALUE(4,2),DATA,FREQ4_SH *VFILL,VALUE(4,3),DATA,(121/FREQ4_SH) *VFILL,VALUE(5,1),DATA,250 *VFILL,VALUE(5,2),DATA,FREQ5_SH *VFILL,VALUE(5,3),DATA,(250/FREQ5_SH) SAVE,TABLE_1 FINISH /CLEAR,NOSTART /OUT, /COM, ===================================================================== /COM, MODELING THE PLATE USING 8-NODE STRUCTURAL SOLID ELEMENT (SOLID185) /COM, ====================================================================== /PREP7 lg = 152.4e-3 ! LENGTH IN METERS wd = 50.8e-3 ! WIDTH IN METERS tk = 2.54e-3 ! THICKNESS IN METERS K,1,-wd/2,0,0 K,2,+wd/2,0,0 K,3,+wd/2,lg,0 K,4,-wd/2,lg,0 K,5,-wd/2,0,tk K,6,+wd/2,0,tk K,7,+wd/2,lg,tk K,8,-wd/2,lg,tk V,1,2,3,4,5,6,7,8 /COM, MATERIAL PROPERTIES OF STRUCTURAL STEEL PLATE MP,EX,1,2.0e+11 MP,DENS,1,7850 MP,NUXY,1,0.3 ET,1,SOLID185 ! 3-D 8 NODE STRUCTURAL SOLID ELEMENT KEYOPT,1,2,3 ! SIMPLIFIED ENHANCED STRAIN FORMULATION TYPE,1 MAT,1 ESIZE,5e-3 VMESH,1 NSEL,S,LOC,Y,0.0 D,ALL,ALL ! CONSTRAINING ALL DOF AT BASE ALLSEL,ALL CM,PLATE,ELEM ! FORMING A COMPONENT WITH ALL ELEMENTS SAVE,SOLID,DB ! SAVE THE DATABASE FINISH /COM, ---------------------- /COM, NO ROTATION /COM, ---------------------- /OUT,SCRATCH /SOLUTION ANTYPE,MODAL MODOPT,LANB,4 ! EXTRACT 4 MODES USING BLOCK-LANCZOS MXPAND,4 SOLVE /OUT, *GET,FREQ1_SO,MODE,1,FREQ FINISH /DELETE,,rst /COM, -------------------------------------- /COM, PLATE ROTATED ALONG X AXIS AT 3200RPM /COM, -------------------------------------- /OUT,SCRATCH /SOLUTION ANTYPE,STATIC OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,3200*pi/30,,,0,OFFSET,0,1,OFFSET,0 ! ROTATING THE PLATE ALONG X AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 AUTOTS,ON NSUBS,10,100,1 OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ2_SO,MODE,1,FREQ FINISH /DELETE,,rst /DELETE,,rstp /COM, -------------------------------------- /COM, PLATE ROTATED ALONG X AXIS AT 9600RPM /COM, -------------------------------------- /OUT,SCRATCH /SOLUTION ANTYPE,STATIC OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,9600*pi/30,,,0,OFFSET,0,1,OFFSET,0 ! ROTATING THE PLATE ALONG X AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 AUTOTS,ON NSUBS,10,100,1 OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ3_SO,MODE,1,FREQ FINISH /DELETE,,rst /DELETE,,rstp /COM, -------------------------------------- /COM, PLATE ROTATED ALONG Z AXIS AT 3200RPM /COM, -------------------------------------- /OUT,SCRATCH /SOLUTION ANTYPE,STATIC OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,3200*pi/30,,,0,OFFSET,0,0,OFFSET,1 ! ROTATING THE PLATE ALONG Z AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 AUTOTS,ON NSUBS,10,100,1 OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ4_SO,MODE,1,FREQ FINISH /DELETE,,rst /DELETE,,rstp /COM, -------------------------------------- /COM, PLATE ROTATED ALONG Z AXIS AT 9600RPM /COM, -------------------------------------- /OUT,SCRATCH /SOLUTION ANTYPE,STATIC OFFSET= -0.1 pi = acos(-1) CMOMEGA,PLATE,9600*pi/30,,,0,OFFSET,0,0,OFFSET,1 ! ROTATING THE PLATE ALONG Z AXIS NLGEOM,ON ! NON-LINEAR ANALYSIS TIME,1.0 AUTOTS,ON NSUBS,10,100,1 OUTRES,ALL,ALL SOLVE FINISH /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB ! LINEAR PERTURBATION ANALYSIS PERTURB,MODAL, ! MODAL ANALYSIS,RETAIN CMOMEGA SOLVE,ELFORM ! REGENERATE STIFFNESS MATRIX MODOPT,LANB,4 MXPAND,4 SOLVE /OUT, *GET,FREQ5_SO,MODE,1,FREQ FINISH /OUT,SCRATCH *DIM,LABEL,CHAR,5,2 *DIM,VALUE,,5,3 LABEL(1,1) = 'None' LABEL(1,2) = '0rpm' LABEL(2,1) = 'X axis' LABEL(2,2) = '3200rpm' LABEL(3,1) = 'X axis' LABEL(3,2) = '9600rpm' LABEL(4,1) = 'Z axis' LABEL(4,2) = '3200rpm' LABEL(5,1) = 'Z axis' LABEL(5,2) = '9600rpm' *VFILL,VALUE(1,1),DATA,90 *VFILL,VALUE(1,2),DATA,FREQ1_SO *VFILL,VALUE(1,3),DATA,(90/FREQ1_SO) *VFILL,VALUE(2,1),DATA,108 *VFILL,VALUE(2,2),DATA,FREQ2_SO *VFILL,VALUE(2,3),DATA,(108/FREQ2_SO) *VFILL,VALUE(3,1),DATA,195 *VFILL,VALUE(3,2),DATA,FREQ3_SO *VFILL,VALUE(3,3),DATA,(195/FREQ3_SO) *VFILL,VALUE(4,1),DATA,121 *VFILL,VALUE(4,2),DATA,FREQ4_SO *VFILL,VALUE(4,3),DATA,(121/FREQ4_SO) *VFILL,VALUE(5,1),DATA,250 *VFILL,VALUE(5,2),DATA,FREQ5_SO *VFILL,VALUE(5,3),DATA,(250/FREQ5_SO) SAVE,TABLE_2 FINISH /NOPR RESUME,TABLE_1 ! /GOPR /OUT,vm281,vrt /COM, /COM, -----------------------------VM281 RESULTS COMPARISON----------------------- /COM, /COM, | TARGET | MECHANICAL APDL | RATIO /COM, /COM, /COM, USING SHELL181 ELEMENTS /COM, *VWRITE,LABEL(1,1),LABEL(1,2),VALUE(1,1),VALUE(1,2),VALUE(1,3) ! https://www.cnblogs.com/gaozihan/p/11200897.html (1X,A8,' ',A8,' ',F12.3,' ',F12.3,' ',F8.3) /COM, /COM, USING SOLID185 ELEMENTS /COM, /NOPR, RESUME,TABLE_2 /GOPR, /COM, *VWRITE,LABEL(1,1),LABEL(1,2),VALUE(1,1),VALUE(1,2),VALUE(1,3) (1X,A8,' ',A8,' ',F12.3,' ',F12.3,' ',F8.3) /COM, /COM,--------------------------------------------------------------------------------- /OUT, *LIST,vm281,vrt ! Output results to vm281.vert FINISH

http://blog.sina.com.cn/s/blog_153e0668a0102x1zg.html large deformation analysis (NLGEOM,ON) includes stress stiffening effect (SSTIF,ON) https://www.bridgehead.com.cn/thread-3367-1-1.html

Output results

-----------------------------VM281 RESULTS COMPARISON-----------------------

| TARGET | MECHANICAL APDL | RATIO

USING SHELL181 ELEMENTS

None 0rpm 90.000 90.831 0.991

X axis 3200rpm 108.000 108.273 0.997

X axis 9600rpm 195.000 195.139 0.999

Z axis 3200rpm 121.000 120.686 1.003

Z axis 9600rpm 250.000 252.359 0.991

USING SOLID185 ELEMENTS

PRINTOUT RESUMED BY /GOP

None 0rpm 90.000 90.875 0.990

X axis 3200rpm 108.000 108.324 0.997

X axis 9600rpm 195.000 195.237 0.999

Z axis 3200rpm 121.000 120.725 1.002

Z axis 9600rpm 250.000 252.419 0.990

-------------------------------------------------------------------------------

Add another example

An episode: the command d,1,all,10,9 is mistakenly entered as d,1,all,10.9

D, Node, Lab, VALUE, VALUE2, NEND, NINC, Lab2, Lab3, Lab4, Lab5, Lab6

d. 1, all, 10.9 means that the degrees of freedom of nodes 1-11 are constrained

d. 1, all, 10.4 means that the degrees of freedom of 1-10 nodes are constrained, so the parameter nend is rounded, and the step size of ninc is 1 by default

d. 1, all, 10.9 and 3 mean that the degrees of freedom of nodes 1, 4, 7 and 10 are constrained

d. 1, all, 10, 9 means that nodes 1 and 10 are constrained

fini /clear /prep7 et,1,shell63,,,,,,,1 r,1,3e-3 mp,ex,1,217e9 mp,nuxy,1,0.3 mp,dens,1,7850 n,1,-0.014,,0.15 n,9,-0.014,,0.478 fill ngen,2,9,1,9,1,0.028 e,1,2,11,10 egen,8,1,-1 finish ! no stress stiff and no spin soft /solu d,1,all,,,10,9 antype,modal modopt,subsp,5 solve !/post1 !set,list *GET,FREQ1,MODE,1,FREQ fini ! with stress stiff and no spin soft /solu antype,static pstres,on omega,314.159265 outpr,,1 solve fini /solu antype,modal modopt,subsp,5 pstres,on omega,314.159265,,,0 solve !/post1 !set,list *GET,FREQ2,MODE,1,FREQ fini ! with stress stiff and with spin soft /solu antype,modal modopt,subsp,5 pstres,on ! Including stress stiffening omega,314.159265,,,1 ! Including rotational softening solve !/post1 !set,list *GET,FREQ3,MODE,1,FREQ fini

First order natural frequency

no stress stiff and no spin soft: 23.96

with stress stiff and no spin soft: 72.21

with stress stiff and with spin soft: 52.01

contrast

Both paragraphs consider stress stiffening and rotation softening, but the codes used are different

shell63 does not support prestressed modal analysis, and shell181 is used for comparison

Fang 1

fini /clear /prep7 et,1,shell181,,,,,,,1 r,1,3e-3 mp,ex,1,217e9 mp,nuxy,1,0.3 mp,dens,1,7850 n,1,-0.014,,0.15 n,9,-0.014,,0.478 fill ngen,2,9,1,9,1,0.028 e,1,2,11,10 egen,8,1,-1 finish ! Fang 1 /solu d,1,all,,,10,9 antype,static omega,314.159265 NLGEOM,ON TIME,1.0 ! The load step time is 1 AUTOTS,ON ! Automatic load step NSUBS,10,100,1 ! Sub step: 10 steps, minimum 1 step, maximum 100 steps outpr,,1 solve fini /SOLUTION ANTYPE,STATIC,RESTART,,,PERTURB PERTURB,MODAL SOLVE,ELFORM modopt,subsp,5 solve *GET,method1_freq1,MODE,1,FREQ *GET,method1_freq2,MODE,2,FREQ *GET,method1_freq3,MODE,3,FREQ *GET,method1_freq4,MODE,4,FREQ *GET,method1_freq5,MODE,5,FREQ fini

Fang 2

fini /clear /prep7 et,1,shell181,,,,,,,1 r,1,3e-3 mp,ex,1,217e9 mp,nuxy,1,0.3 mp,dens,1,7850 n,1,-0.014,,0.15 n,9,-0.014,,0.478 fill ngen,2,9,1,9,1,0.028 e,1,2,11,10 egen,8,1,-1 finish ! Fang 2 /solu d,1,all,,,10,9 antype,static pstres,on omega,314.159265 outpr,,1 solve fini /solu antype,modal modopt,subsp,5 pstres,on ! Including stress stiffening omega,314.159265,,,1 ! Including rotational softening solve *GET,method2_freq1,MODE,1,FREQ *GET,method2_freq2,MODE,2,FREQ *GET,method2_freq3,MODE,3,FREQ *GET,method2_freq4,MODE,4,FREQ *GET,method2_freq5,MODE,5,FREQ fini

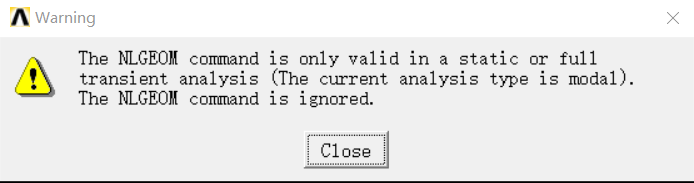

NLGEOM can only be used for static and full transient analysis.

NLGEOM,ON

There are two kinds of large deflection effects: large deflection (large rotation) effect and large strain effect, depending on the element type. When NLGEOM is turned on, the stress stiffening effect will also be automatically included

The first five modal frequencies of the two methods are compared

Slightly different

Why are the results different

Both codes are verification manuals. The former is version 15, and the latter is not found in version 15. I guess it is old. (check the command of version 2021). Now the OMEGA command has only three parameters, and there is no fourth parameter to set rotation softening. In CORIOLIS, rotation softening is mentioned as the default consideration of ansys.

Thermal fluid solid coupling

Fluid solid coupling

Thermo solid coupling

Heat flow coupling

Thermal fluid solid coupling