Blanking of cans

Problem: a company uses a set of stamping equipment to produce a can for canned drinks, which is stamped with tinplate The can is cylindrical, including the can body, upper cover and lower bottom. The height of the can is 10 cm, and the diameters of the upper cover and lower bottom are 5 cm The company uses two different specifications of tinplate raw materials: the tinplate of specification 1 is square with a side length of 24 cm; The tinplate of specification 2 is rectangular, with length and width of 32 cm and 28 cm respectively Due to the limitation of production equipment and production process, the tinplate raw materials of specification I can only be stamped according to mode 1, mode 2 or mode 3 in Figure 1; For tinplate material of specification 2, stamping can only be carried out according to mode 4 The time required for each stamping using mode 1, mode 2, mode 3 and mode 4 is 1.5 s, 2 s, 1 s and 3 s respectively

The factory works 40 h ours a week, and the available raw materials of tinplate with specification 1 and specification 2 are 50000 and 20000 respectively At present, the profit of each can is 0.10 yuan, and the loss of raw materials is 0.5% 001 yuan / cm3 (if the can body, upper cover or lower bottom cannot be assembled into a pop-up can for sale at the weekend, it is also regarded as the loss of raw materials)

Solution & results

model :

sets :

row/1..4/ : remain, x, stampingTime, spec1, spec2, body, bottom;

endsets

calc :

pi = @acos(-1); !pi value;

s1 = pi * 5 *10; !Tank body area;

s2 = pi * 5 ^ 2 / 4; !Tank bottom or cover area;

remain(1) = 24 * 24 - s1 - 10 * s2; !Mode 1 residual material loss;

remain(2) = 24 * 24 - 2 * s1 - 4 * s2; !Mode 2 residual material loss;

remain(3) = 24 * 24 - 16 * s2; !Mode 3 residual material loss;

remain(4) = 32 * 28 - 4 * s1 - 5 * s2; !Mode 4 residual material loss;

totalTime = 40 * 3600; !Total time;

endcalc

data :

stampingTime = 1.5, 2, 1, 3; !Stamping time;

spec1 = 1, 1, 1, 0; !Specification 1;

spec2 = 0, 0, 0, 1; !Specification 2;

totalSpec1 = 50000; !Specification 1 total;

totalSpec2 = 20000; !Specification 2 total;

body = 1, 2, 0, 4; !Number of tank bodies per mode;

bottom = 10, 4, 16, 5; !Number of tank bottoms or lids per mode;

enddata

max = 0.1 * count - 0.001 * (@sum(row : remain * x) + s1 * L1 + s2 * L2);

@sum(row : stampingTime * x) <= totalTime;

@sum(row : spec1 * x) <= totalSpec1;

@sum(row : spec2 * x) <= totalSpec2;

count <= @sum(row : body * x);

2 * count <= @sum(row : bottom * x);

L1 = @sum(row : body * x) - count;

L2 = @sum(row : bottom * x) - 2 * count;

@for(row : @gin(x));

@gin(count); @gin(L1); @gin(L2);

end

Global optimal solution found.

Objective value: 4298.014

Objective bound: 4298.014

Variable Value Reduced Cost

COUNT 160250.0 -0.1000000

L1 0.000000 0.1570796

L2 0.000000 0.1963495E-01

X( 1) 0.000000 0.2225708

X( 2) 40125.00 0.1833009

X( 3) 3750.000 0.2618407

X( 4) 20000.00 0.1695067

Natural casing problem

Question: the production and processing of natural casings is a traditional industry in China. After cleaning and finishing, the casing is divided into small sections (raw materials) with different lengths and enters the assembly process. The traditional production method relies on manual calculation while measuring the length of raw materials, and the finished products (bundles) are assembled according to the specified number and total length of raw materials. Raw materials are divided into grades according to length, usually with o.5 m as the first grade. For example, 14-14.4m is calculated as 14m, 14.5m-14.9m is calculated as 14.5m, and the rest are calculated as follows.

All modes

%%

clear, close, clc

tic

%%

l = [14 : 0.5 : 22.5, 23.5, 25.5]; % 20 Species length

a = [35,29,30,42,28,42,45,49,50,64,52,63,49,35,27,16,12,2,6,1]; %20 Number of raw materials

cnt1 = floor(sum(a) / 4); % The maximum number of bales can be obtained from the total number of bales

cnt2 = floor(l * a' / 88.5); % The maximum number of bales can be obtained from the total meters

fprintf('The maximum number of bales is:%5d\n', min(cnt1, cnt2))

n = size(l, 2);

aMin = zeros(1, n); % Initialize the maximum number of type casings of various lengths

for i = 1 : n

aMin(i) = min([5, floor(89.5 / l(i)), a(i)]); % Maximum number of types of casings of various lengths

end

count = 0;

res = zeros(1, 20);

result = zeros(1, 20);

for i1 = 0 : aMin(1)

result(1) = i1;

Len = result * [l(1 : 1), zeros(1,n - 1)]';

Gen = sum(result(1 : 1));

if Len > 89.5 || Gen > 5

break;

end

for i2 = 0 : aMin(2)

result(2) = i2;

Len = result * [l(1 : 2), zeros(1,n - 2)]';

Gen = sum(result(1 : 2));

if Len > 89.5 || Gen > 5

break;

end

for i3 = 0 : aMin(3)

result(3) = i3;

Len = result * [l(1 : 3), zeros(1,n - 3)]';

Gen = sum(result(1 : 3));

if Len > 89.5 || Gen > 5

break;

end

for i4 = 0 : aMin(4)

result(4) = i4;

Len = result * [l(1 : 4), zeros(1,n - 4)]';

Gen = sum(result(1 : 4));

if Len > 89.5 || Gen > 5

break;

end

for i5 = 0 : aMin(5)

result(5) = i5;

Len = result * [l(1 : 5), zeros(1,n - 5)]';

Gen = sum(result(1 : 5));

if Len > 89.5 || Gen > 5

break;

end

for i6 = 0 : aMin(6)

result(6) = i6;

Len = result * [l(1 : 6), zeros(1,n - 6)]';

Gen = sum(result(1 : 6));

if Len > 89.5 || Gen > 5

break;

end

for i7 = 0 : aMin(7)

result(7) = i7;

Len = result * [l(1 : 7), zeros(1,n - 7)]';

Gen = sum(result(1 : 7));

if Len > 89.5 || Gen > 5

break;

end

for i8 = 0 : aMin(8)

result(8) = i8;

Len = result * [l(1 : 8), zeros(1,n - 8)]';

Gen = sum(result(1 : 8));

if Len > 89.5 || Gen > 5

break;

end

for i9 = 0 : aMin(9)

result(9) = i9;

Len = result * [l(1 : 9), zeros(1,n - 9)]';

Gen = sum(result(1 : 9));

if Len > 89.5 || Gen > 5

break;

end

for i10 = 0 : aMin(10)

result(10) = i10;

Len = result * [l(1 : 10), zeros(1,n - 10)]';

Gen = sum(result(1 : 10));

if Len > 89.5 || Gen > 5

break;

end

for i11 = 0 : aMin(11)

result(11) = i11;

Len = result * [l(1 : 11), zeros(1,n - 11)]';

Gen = sum(result(1 : 11));

if Len > 89.5 || Gen > 5

break;

end

for i12 = 0 : aMin(12)

result(12) = i12;

Len = result * [l(1 : 12), zeros(1,n - 12)]';

Gen = sum(result(1 : 12));

if Len > 89.5 || Gen > 5

break;

end

for i13 = 0 : aMin(13)

result(13) = i13;

Len = result * [l(1 : 13), zeros(1,n - 13)]';

Gen = sum(result(1 : 13));

if Len > 89.5 || Gen > 5

break;

end

for i14 = 0 : aMin(14)

result(14) = i14;

Len = result * [l(1 : 14), zeros(1,n - 14)]';

Gen = sum(result(1 : 14));

if Len > 89.5 || Gen > 5

break;

end

for i15 = 0 : aMin(15)

result(15) = i15;

Len = result * [l(1 : 15), zeros(1,n - 15)]';

Gen = sum(result(1 : 15));

if Len > 89.5 || Gen > 5

break;

end

for i16 = 0 : aMin(16)

result(16) = i16;

Len = result * [l(1 : 16), zeros(1,n - 16)]';

Gen = sum(result(1 : 16));

if Len > 89.5 || Gen > 5

break;

end

for i17 = 0 : aMin(17)

result(17) = i17;

Len = result * [l(1 : 17), zeros(1,n - 17)]';

Gen = sum(result(1 : 17));

if Len > 89.5 || Gen > 5

break;

end

for i18 = 0 : aMin(18)

result(18) = i18;

Len = result * [l(1 : 18), zeros(1,n - 18)]';

Gen = sum(result(1 : 18));

if Len > 89.5 || Gen > 5

break;

end

for i19 = 0 : aMin(19)

result(19) = i19;

Len = result * [l(1 : 19), zeros(1,n - 19)]';

Gen = sum(result(1 : 19));

if Len > 89.5 || Gen > 5

break;

end

for i20 = 0 : aMin(20)

result(20) = i20;

Len = result * [l([1 : 20]), zeros(1,n - 20)]';

Gen = sum(result);

if Len >= 88.5 && Len <= 89.5 && Gen >= 4 && Gen <= 5

count = count + 1;

res(count, :) = result;

if i20 == 1

result(20) = 0;

break;

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

end

%%

toc

%% File write

fid = fopen('changyi.txt', 'w');

for i = 1 : size(res, 1);

for j = 1 : 20

fprintf(fid, "%3d", res(i, j));

end

fprintf(fid, "\n");

end

fclose(fid);

result

All compliant modes 1.txt

Solving the optimal mode

Model :

Sets :

row/1..2783/ : x, y;

col/1..20/ : l, a;

link(row, col) : b;

Endsets

Data :

l=14,14.5,15,15.5,16,16.5,17,17.5,18,18.5,19,19.5,20,20.5,21,21.5,22,22.5,23.5,25.5;

a=35,29,30,42,28,42,45,49,50,64,52,63,49,35,27,16,12,2,6,1;

b = @file('changyi1.txt');

@text('30.txt') = @writefor(row(i) | x(i) #gt# 0 : @name(x), ' ', x(i), @newline(1));

Enddata

Min = z3;

137 = @sum(row : x); !Objective function 1;

3 = x(1) + x(2) + x(3); !Objective function 2;

z3 = @sum(row : y); !Objective function 3;

@for(col(j) : @sum(row(i) : x(i) * b(i, j)) <= a(j)); !Raw material constraints;

@for(row : x <= 10000 * y);

@for(row : x >= y);

@for(row : @gin(x));

@for(row : @bin(y));

End

Feasible solution found.

Objective value: 14.00000

Objective bound: 8.000000

Infeasibilities: 0.000000

Extended solver steps: 126503

Total solver iterations: 4318795

%%

clear, close, clc

%% read in data

load 1.txt

totalModel = X1;

[~, modelRow, ~, modelNum] = textread('10.txt','%s %d %s %d');

x = [modelRow, modelNum];

%%

l = [14 : 0.5 : 22.5, 23.5, 25.5]; % 20 Species length

a = [35,29,30,42,28,42,45,49,50,64,52,63,49,35,27,16,12,2,6,1]; %20 Number of raw materials

totalGen = 0; % Total number

totalKun = 0; % Total bales

totalLen = 0; % Total length

for i = 1 : length(modelRow)

preLen = 0; % Current length

preGen = 0; % Current number

i1 = modelRow(i);

for k = 1 : length(l)

preLen = preLen + totalModel(i1, k) * l(k);

preGen = preGen + totalModel(i1, k);

end

fprintf("The first%02d Line, mode%04d Is:", i, x(i, 1));

for j = 1 : length(l)

if totalModel(i1, j) > 0

fprintf('(%3.1f rice, %1d root )', l(j), totalModel(i1, j))

end

end

fprintf('length%3.1f Meters,%1d Root,%2d bundle \n', preLen, preGen, x(i, 2))

totalLen = totalLen + preLen * x(i, 2);

totalKun = totalKun + x(i, 2);

totalGen = totalGen + preGen * x(i, 2);

end

fprintf('Total length%6.1f, Total number%6d, Total bales%5d\n',totalLen, totalGen, totalKun);

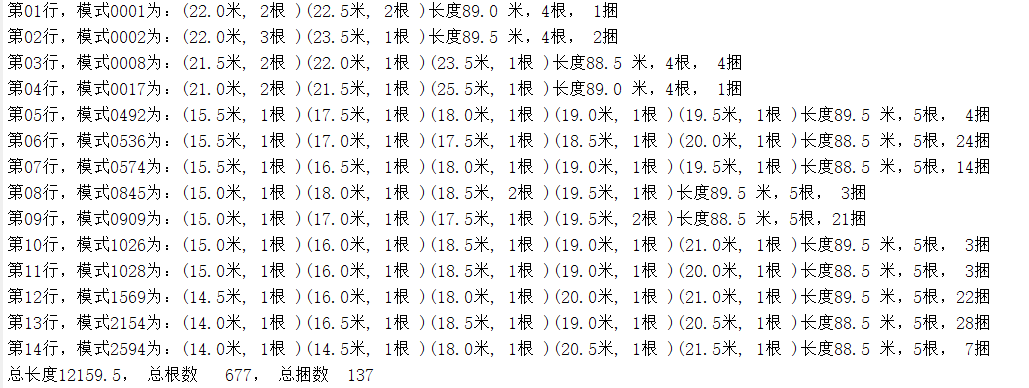

result

If there are errors and areas that can be improved, please leave a message in the comment area below!