PLC programming of EtherCAT motion controller (III) electronic gear

Electronic gear mode can connect two or more shafts to achieve accurate synchronous motion, so as to replace the traditional mechanical gear connection.

The following axis is called the spindle, and the following axis is the slave axis. By connecting the following axis to the spindle according to a certain ratio, when the spindle moves, the connected following axis also follows the movement. The number of pulses is connected at the same time, and the proportion of UNITS of different axes shall be considered.

Part I function of electronic gear

1. Pulse compensation to reduce the burden on the upper computer (because the current pulse transmitting elements are limited by the pulse transmission frequency).

2. Match the number of pulses sent by the motor with the minimum movement of the machine, and set the movement of the workpiece (or motor) corresponding to one pulse of the command input to any value; It can realize the stepless speed change of the motor, and can prevent out of step and overshoot when the motor starts and stops, so as to give full play to the potential of the motor.

3. Transfer synchronous motion information, realize coordinate linkage, transformation between motion forms (rotation rotation, rotation straight line, straight line), simplified control, etc.

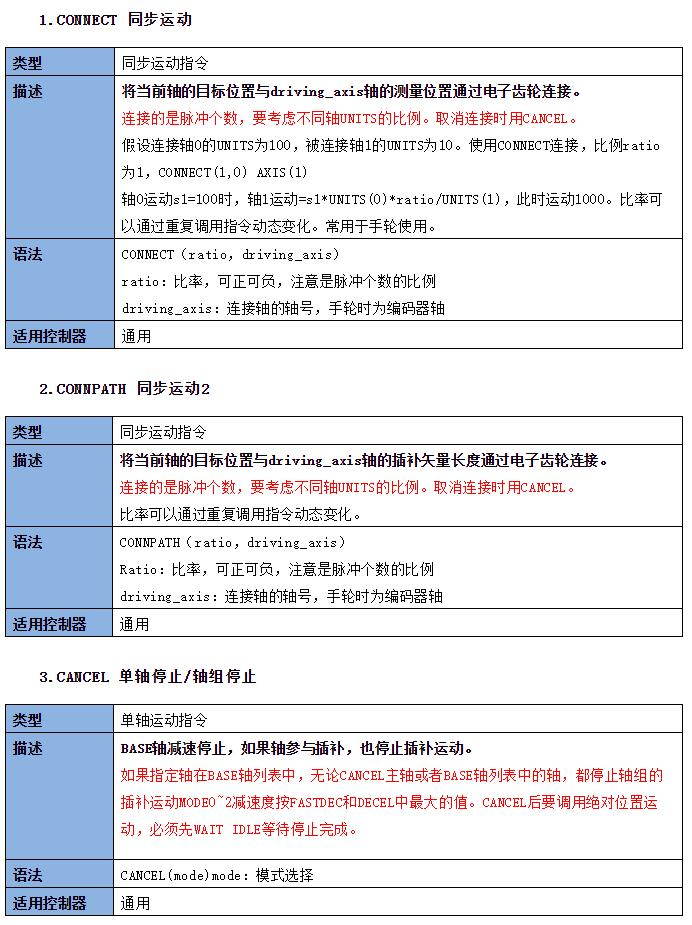

Part II instruction description of electronic gear

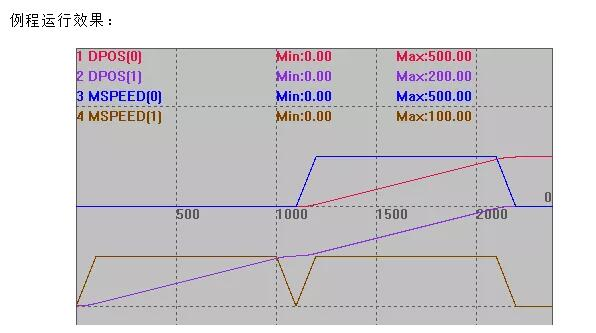

4. Use routine of electronic gear

RAPIDSTOP(2)

WAIT IDLE(0)

WAIT IDLE(1)

BASE(0,1)

ATYPE=1,1

UNITS=100,1000

DPOS=0,0

SPEED=100,100

ACCEL=1000,1000

DECEL=1000,1000

TRIGGER 'Automatic trigger oscilloscope

MOVE(100) AXIS(1) 'Axis 1 moves 100 and axis 0 does not move at this time

WAIT IDLE(1) 'The previous motion is not connected

CONNECT(0.5,1) AXIS(0) 'Axis 0 is connected to axis 1 with a ratio of 0.5

'CONNPATH(0.5,1) AXIS(0) 'Axis 0 is connected to axis 1 with a ratio of 0.5

MOVE(100) AXIS(1) 'Axis 1 movement 100

Axis 0 movement distance: 100*1000*0.5/100=500

5. Instructions and precautions

CONNECT synchronous motion and CONNPATH synchronous motion 2 are both electronic gear connection commands, and their syntax rules are the same.

CONNECT is connected to the measurement length. The number of pulses sent by the spindle single axis * connection ratio = the number of pulses sent by the following axis, that is, when the connection ratio is the same, the number of pulses sent by the spindle single axis is equal to the number of pulses sent by the following axis.

CONNPATH connects the interpolation vector length. The number of pulses sent by the interpolation synthesis axis * connection ratio = the number of pulses sent by the following axis, that is, when the connection ratio is the same, the number of pulses sent by the interpolation motion synthesized by the main axis and other axes is the same as that sent by the following axis.

CONNPATH has the same effect of motion as CONNECT if it is connected to a single axis.

Part III Application Cases of electronic gears

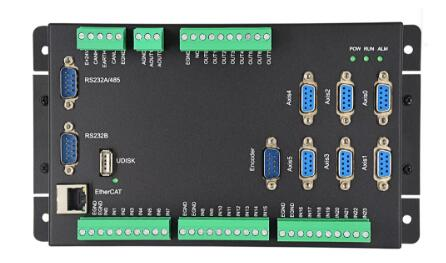

1. Schematic diagram of controller

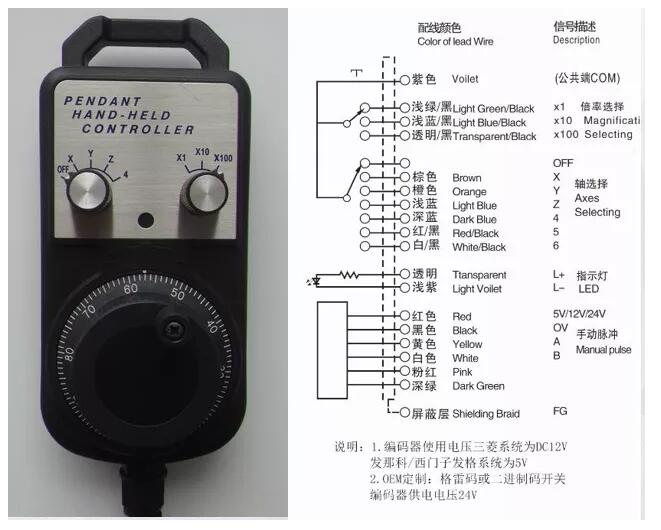

Schematic diagram of ZMC006CE handwheel interface (Encoder)

2. Schematic diagram of hand wheel

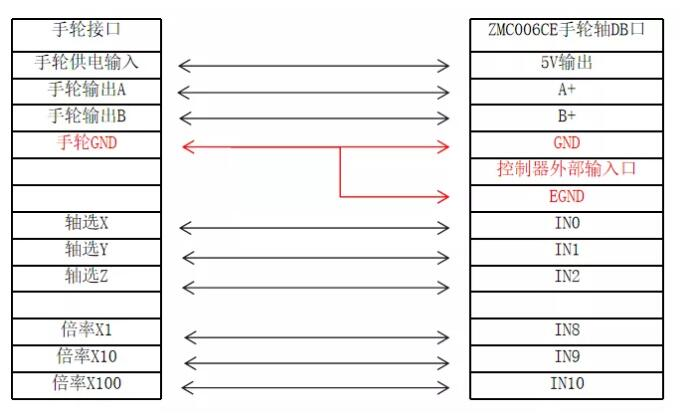

3. Wiring between handwheel and ZMC006CE handwheel shaft

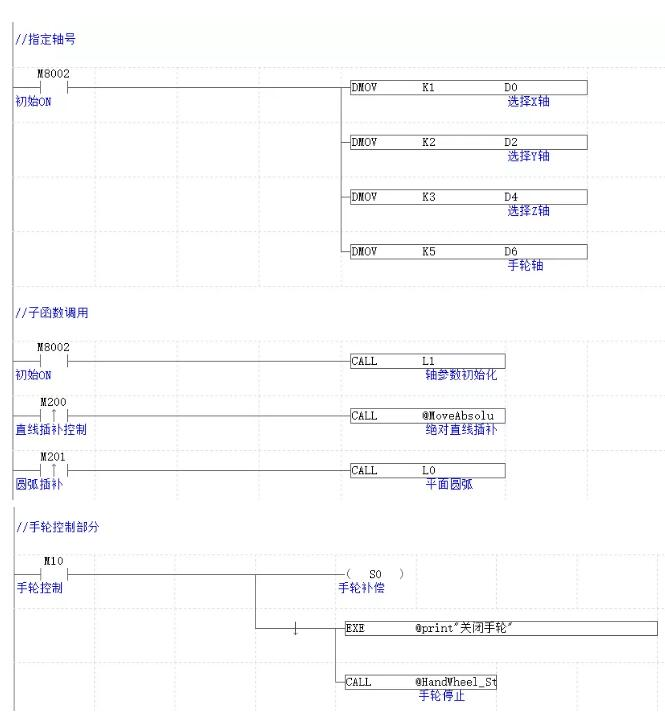

4. Handwheel position compensation - ladder routine

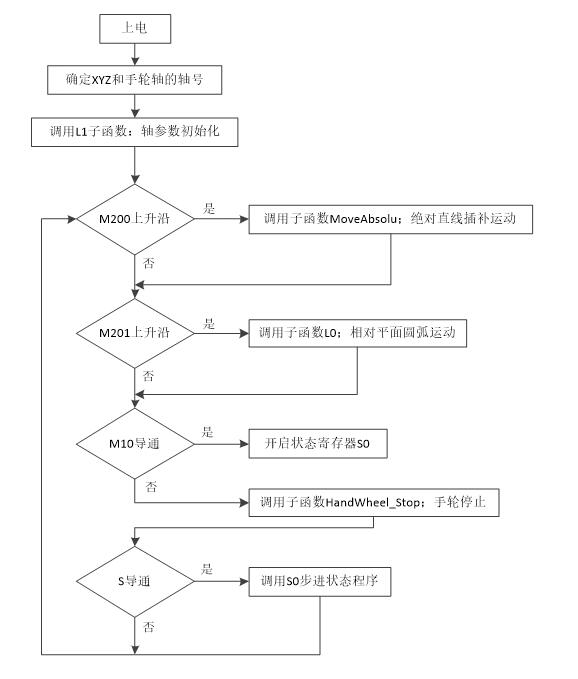

Ladder program structure: after power on, cycle scanning to judge the state of auxiliary relay M, so as to call different subroutines for execution. The status of auxiliary relay M is controlled by HMI interface.

Handwheel application ladder program:

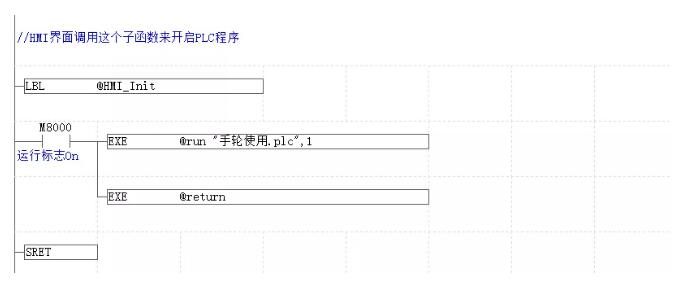

The following sub function has nothing to do with the main program. It is used to start the PLC file task in the HMI initialization function. The upper PLC file is opened by the automatic operation task number. If the automatic operation of PLC file is not set, the lower program can be called.

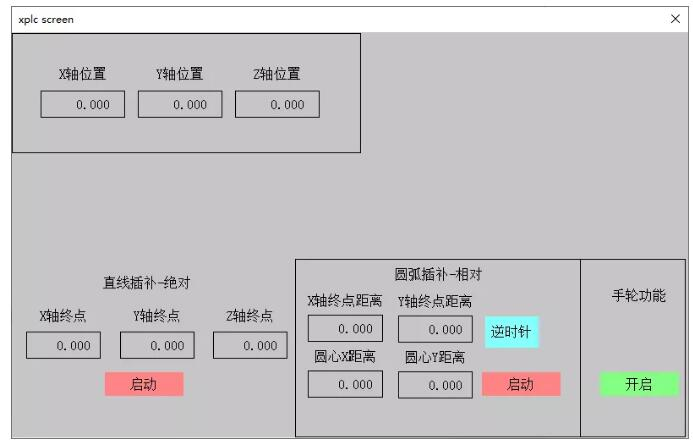

Hand wheel application case interface effect

//Specify shaft number

ld m8002

DMOV K1 D0

DMOV K2 D2

DMOV K3 D4

DMOV K5 D6

//Sub function call

ld m8002

CALL L1

LDP M200

CALL @MoveAbsolu

LDP M201

CALL L0

//Handwheel control part

LD M10

out s0

ed

exe @print"Close the handwheel"

call @HandWheel_Stop

//Handwheel control part: select the drive shaft and connection ratio according to the knob

STL S0

MPS

AND X0

EXE @CONNECT(modbus_long(10),modbus_long(6)) AXIS(modbus_long(0))

MRD

AND X1

EXE @CONNECT(modbus_long(10),modbus_long(6)) AXIS(modbus_long(2))

MRD

AND X2

EXE @CONNECT(modbus_long(10),modbus_long(6)) AXIS(modbus_long(4))

MRD

call @HandWheel_Stop

AND X10

DMOV K1 D10

MRD

AND X11

DMOV K10 D10

MPP

AND X12

DMOV K100 D10

RET

fend

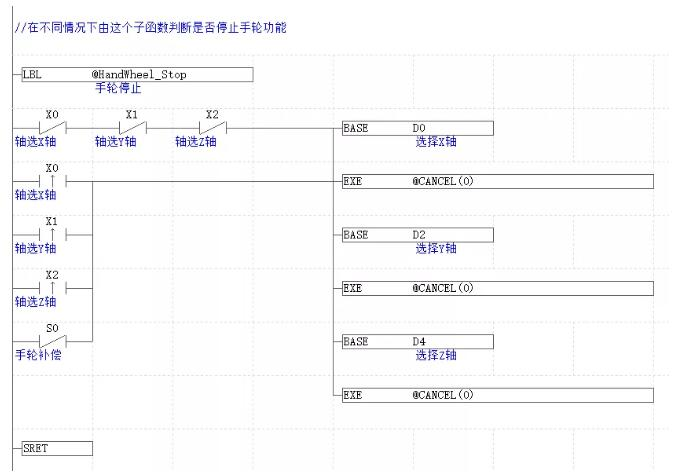

//In different cases, this sub function determines whether to stop the handwheel function

lbl @HandWheel_Stop

ldi x0

ANI X1

ANI X2

ORP X0

ORP X1

ORP X2

ORI S0

Base d0

exe @CANCEL(0)

Base d2

exe @CANCEL(0)

base d4

exe @CANCEL(0)

sret

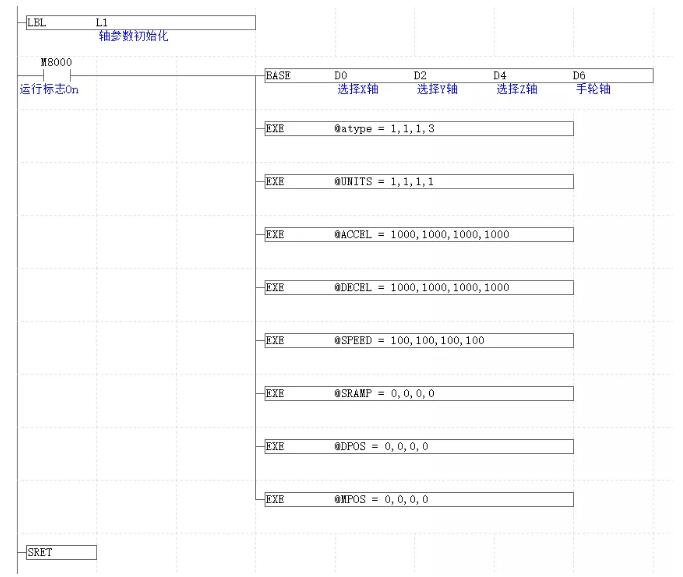

//Initialize selection axis

lbl l1

ld m8000

BASE D0 D2 D4 D6

EXE @atype = 1,1,1,3

EXE @UNITS = 1,1,1,1

EXE @ACCEL = 1000,1000,1000,1000

EXE @DECEL = 1000,1000,1000,1000

EXE @SPEED = 100,100,100,100

EXE @SRAMP = 0,0,0,0

EXE @DPOS = 0,0,0,0

EXE @MPOS = 0,0,0,0

sret

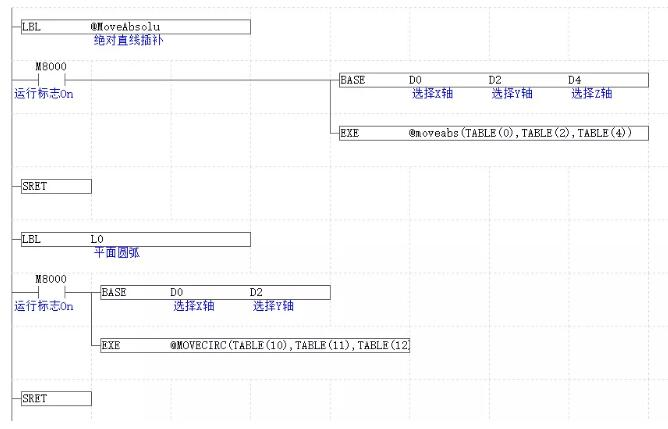

LBL @MoveAbsolu

ld m8000

base d0 d2 d4

exe @moveabs(TABLE(0),TABLE(2),TABLE(4))

sret

LBL l0

ld m8000

base d0 d2

exe @MOVECIRC(TABLE(10),TABLE(11),TABLE(12),TABLE(13),MODBUS_BIT(100))

sret

This time, the PLC programming of EtherCAT motion controller (III) - electronic gear is shared here.

For more interesting content, please pay attention to the "public assistant" official account, and you need the relevant development environment and routine code. Please consult the sales engineer of the sports technology.

This article is original by positive motion technology. You are welcome to reprint it and learn together to improve China's intelligent manufacturing level. The copyright of this article belongs to rightmovement technology. If you reprint it, please indicate the source of the article.