STM32F103 register mode turns on the LED water flow lamp

1, GPIO port initialization

You need to check the stm32 user manual here

Download link https://pan.baidu.com/s/1Q0jdfFsd39dN2aUyjaMXUw Extraction code zxwn

1. Clock configuration

GPIOA, B and C ports are used in this experiment. All three ports belong to APB2 bus

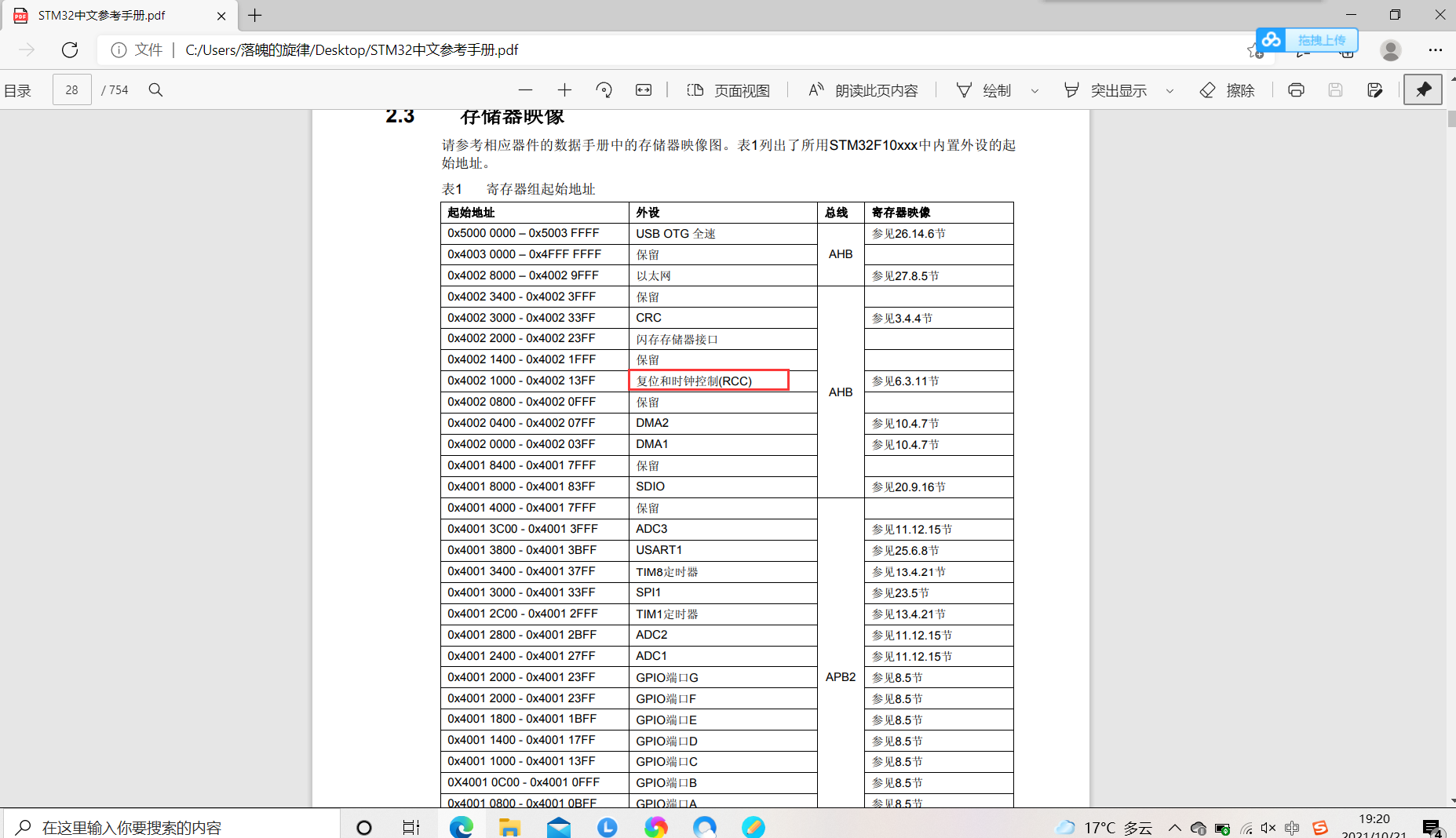

1. Find the clock enable register mapping base address

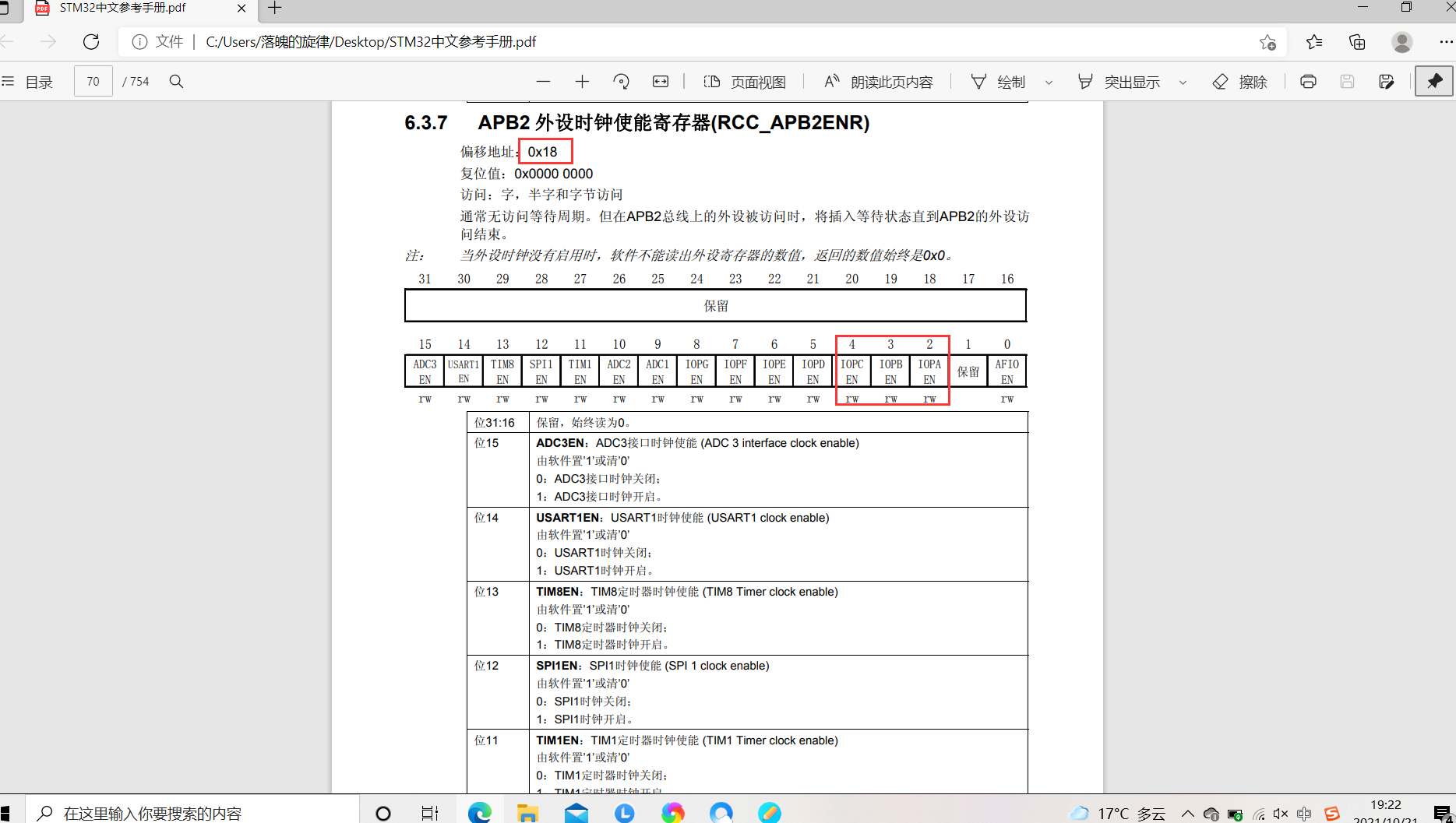

2. Find the port offset address and the location of the corresponding port

3. Enable the corresponding port clock

//----------------APB2 enable clock register--------------------- #define RCC_APB2ENR *((unsigned volatile int*)0x40021018) RCC_APB2ENR|=1<<2|1<<3|1<<4; //APB2-GPIOA, GPIOB, GPIOC peripheral clock enable

2. Input / output mode and output rate setting

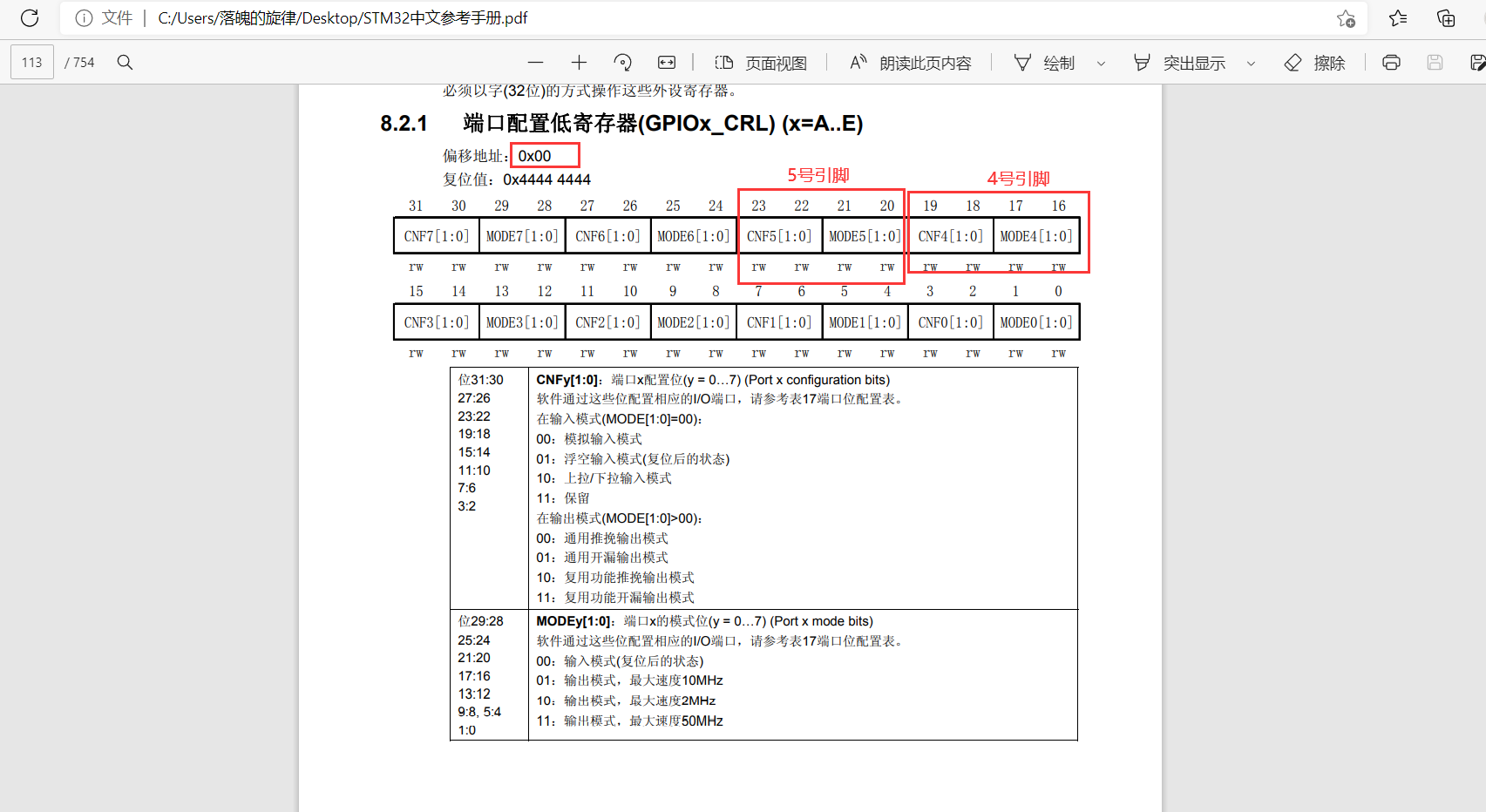

This experiment adopts the general push-pull output mode, and the maximum output clock frequency is 2Mhz. A4, B5 and C14 pins are used respectively. A4 and B5 belong to port configuration, the low register offset address is 0x00, and C13 belongs to port configuration, and the high register offset address is 0x04.

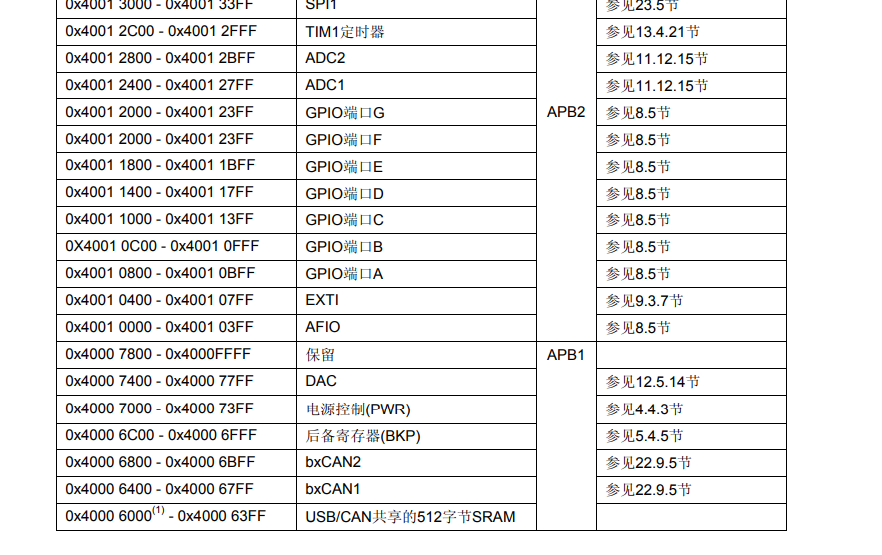

GPIOx port base address found

Configure the corresponding pin register, base address + offset

//----------------GPIOA configuration register----------------------- #define GPIOA_CRL *((unsigned volatile int*)0x40010800) //----------------GPIOB configuration register----------------------- #define GPIOB_CRL *((unsigned volatile int*)0x40010C00) //----------------GPIOC configuration register----------------------- #define GPIOC_CRH *((unsigned volatile int*)0x40011004)

Set the output mode as push-pull output and the output speed as 2Mhz

GPIOA_CRL&=0xFFF0FFFF; //Set bit reset GPIOA_CRL|=0x00020000; //PA4 push-pull output changes bits 19, 18, 17 and 16 to 0010 GPIOB_CRL&=0xFF0FFFFF; //Set bit reset GPIOB_CRL|=0x00200000; //PB5 push-pull output changes the 23rd, 22nd, 21st and 20th to 0010 GPIOC_CRH&=0xFF0FFFFF; //Set bit reset GPIOC_CRH|=0x00200000; //PC14 push-pull output changes the 23rd, 22nd, 21st and 20th to 0010

2, Experimental process

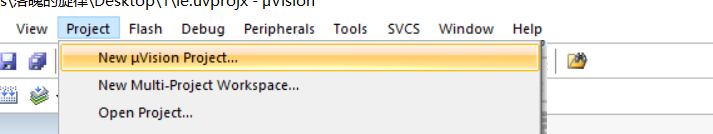

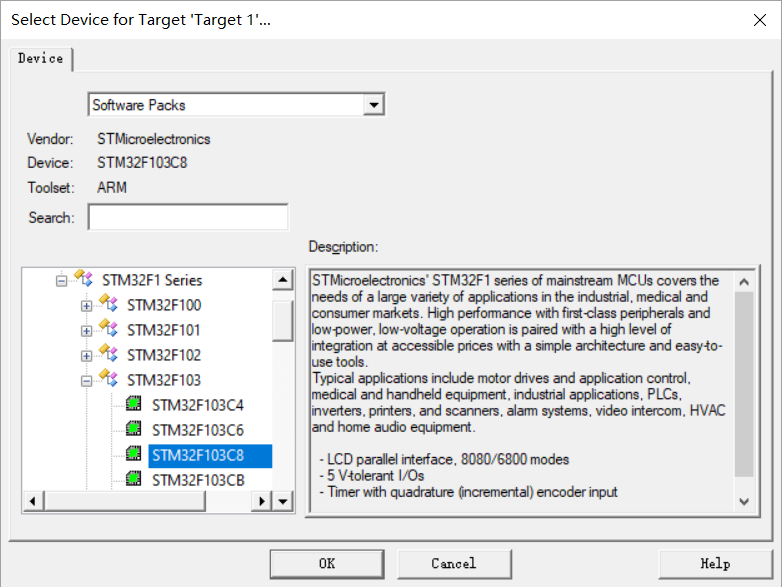

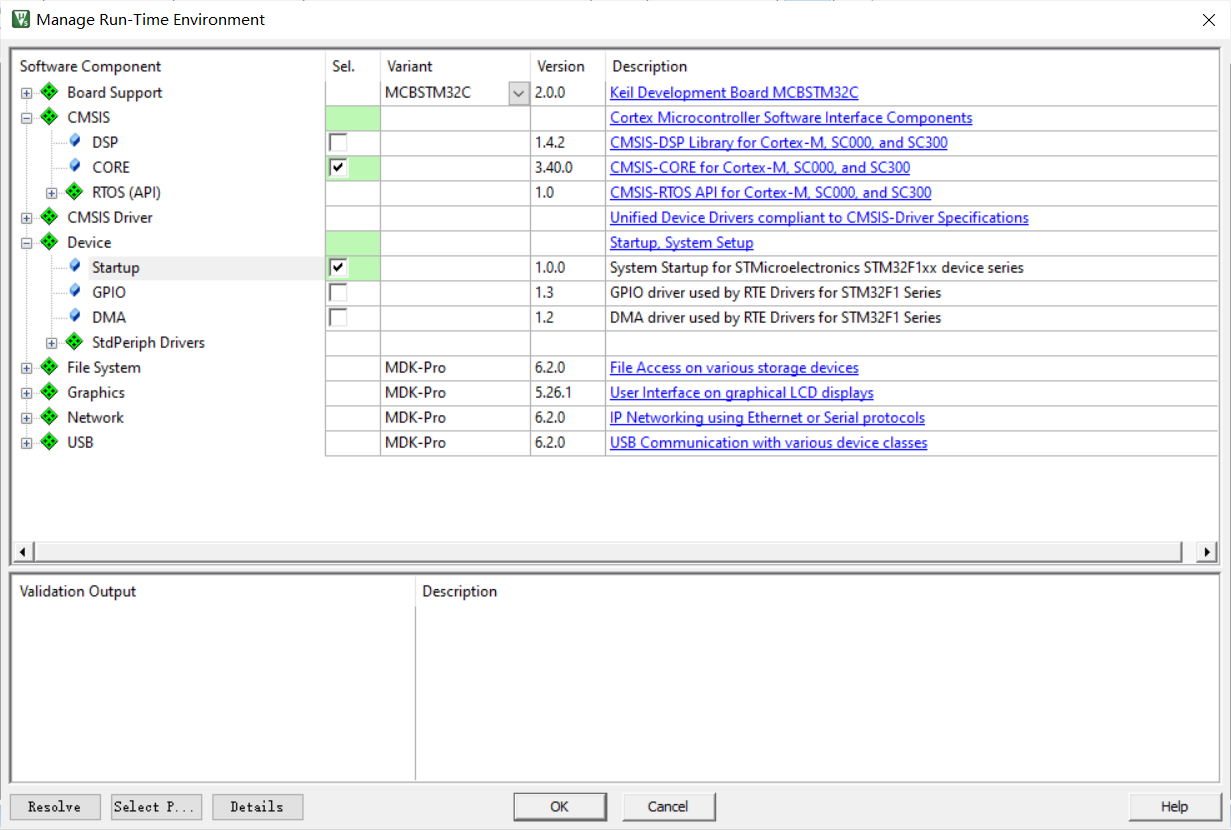

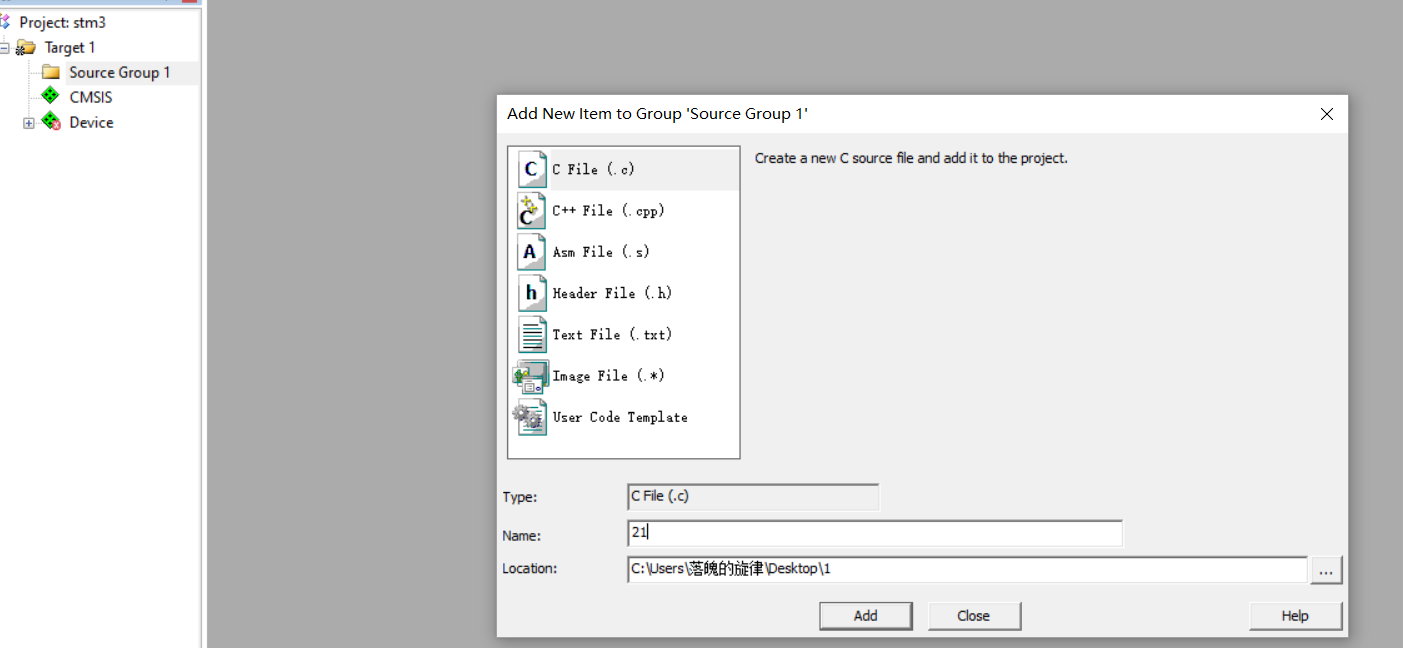

1. keil compiler

1. Click Project to create a new Project file

2. Name the project, select STM32F103C8, and click OK

3. Check core in CMSIS, check Statuo under device, and click OK

4. Click the + sign on the left of Target 1, right-click Source Group 1, select Add new item, and select generate. c file.

c language code

#include "stm32f10x.h"

//----------------APB2 enable clock register---------------------

#define RCC_APB2ENR *((unsigned volatile int*)0x40021018)

//----------------GPIOA configuration register-----------------------

#define GPIOA_CRL *((unsigned volatile int*)0x40010800)

#define GPIOA_ODR *((unsigned volatile int*)0x4001080C)

//----------------GPIOB configuration register-----------------------

#define GPIOB_CRL *((unsigned volatile int*)0x40010C00)

#define GPIOB_ODR *((unsigned volatile int*)0x40010C0C)

//----------------GPIOC configuration register-----------------------

#define GPIOC_CRH *((unsigned volatile int*)0x40011004)

#define GPIOC_ODR *((unsigned volatile int*)0x4001100C)

//Delay Functions

void Delay()

{

u32 i=0;

for(;i<5000000;i++);

}

int main(void)

{

RCC_APB2ENR|=1<<2|1<<3|1<<4; //APB2-GPIOA, GPIOB, GPIOC peripheral clock enable

GPIOA_CRL&=0xFFF0FFFF; //Set bit reset

GPIOA_CRL|=0x00020000; //PB5 push pull output

GPIOA_ODR&=~(1<<4); //Set the initial light to off

GPIOB_CRL&=0xFF0FFFFF; //Set bit reset

GPIOB_CRL|=0x00200000; //PB5 push pull output

GPIOB_ODR&=~(1<<5); //Set the initial light to off

GPIOC_CRH&=0xF0FFFFFF; //Set bit reset

GPIOC_CRH|=0x02000000; //PB5 push pull output

GPIOC_ODR&=~(1<<14); //Set the initial light to off

while(1){

//A lamp

GPIOA_ODR|=1<<4; //PB5 high level

Delay();

GPIOA_ODR&=~(1<<4); //PB5 low level is set to 0, so press bit and

//B lamp

GPIOB_ODR|=1<<5; //PB5 high level

Delay();

GPIOB_ODR&=~(1<<5); //PB5 low level is set to 0, so press bit and

//C lamp

GPIOC_ODR|=1<<14; //PB5 high level

Delay();

GPIOC_ODR&=~(1<<14); //PB5 low level is set to 0, so press bit and

}

}

Assembly code (I completed this experiment with c language code)

AREA MYDATA, DATA

AREA MYCODE, CODE

ENTRY

EXPORT led

led

;Enable A,B,C

ldr r0, =0x40021018

ldr r1, =0x0000001c

str r1, [r0]

;configure port A4

ldr r0, =0x40010800

ldr r1, [r0]

bic r1, r1, #0x000f0000

orr r1, r1, #0x00010000

str r1, [r0]

;configure port B5

ldr r0, =0x40010c00

ldr r1, [r0]

bic r1, r1, #0x00f00000

orr r1, r1, #0x00100000

str r1, [r0]

;configure port C14

ldr r0, =0x40011004

ldr r1, [r0]

bic r1, r1, #0x0f000000

orr r1, r1, #0x01000000

str r1, [r0]

;Initially A4 Light up

ldr r0, =0x4001080c

ldr r1, =0x00000010

str r1, [r0]

ldr r0, =5000000;frequency

ldr r1, =0

;Cycle light

blink

add r1, r1, #1

cmp r1, r0

blt blink

;A4 Extinguish

ldr r1, =0x4001080c

ldr r2, [r1]

eor r2, r2, #0x00000010

str r2, [r1]

;B5 bright

ldr r1, =0x40010c0c

ldr r2, [r1]

eor r2, r2, #0x00000020

str r2, [r1]

ldr r1, =0

blink1

add r1, r1, #1

cmp r1, r0

blt blink1

;B5 Extinguish

ldr r1, =0x40010c0c

ldr r2, [r1]

eor r2, r2, #0x00000020

str r2, [r1]

;C14 bright

ldr r1, =0x4001100c

ldr r2, [r1]

eor r2, r2, #0x00004000

str r2, [r1]

ldr r1, =0

blink2

add r1, r1, #1

cmp r1, r0

blt blink2

;C14 Extinguish

ldr r1, =0x4001100c

ldr r2, [r1]

eor r2, r2, #0x00004000

str r2, [r1]

;A4 bright

ldr r1, =0x4001080c

ldr r2, [r1]

eor r2, r2, #0x00000010

str r2, [r1]

ldr r1, =0

b blink

END

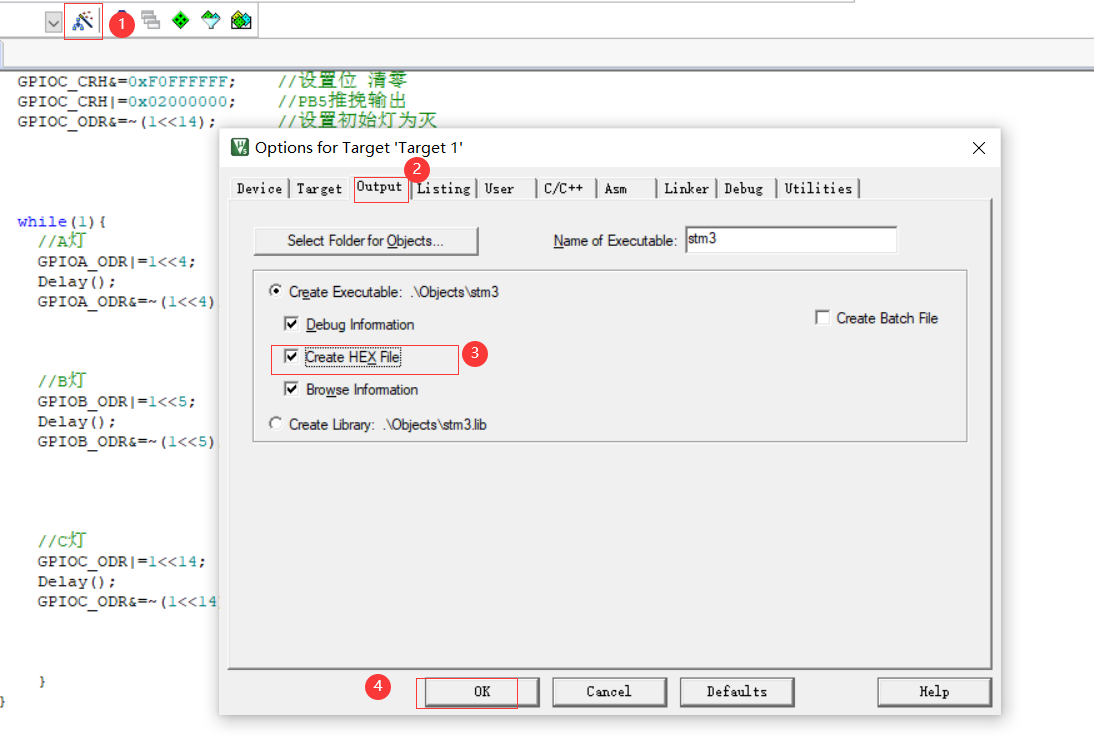

Then click the magic wand and select great hex file

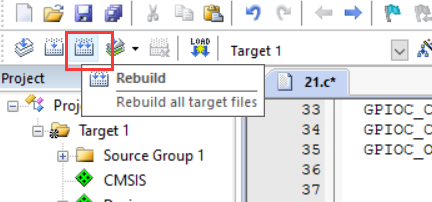

Click Rebuild

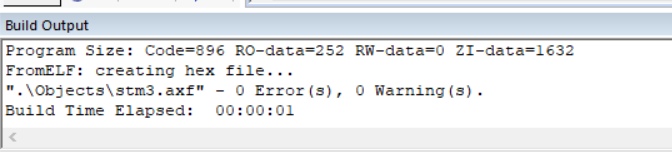

The program can generate HEX file without error

2. Burning operation

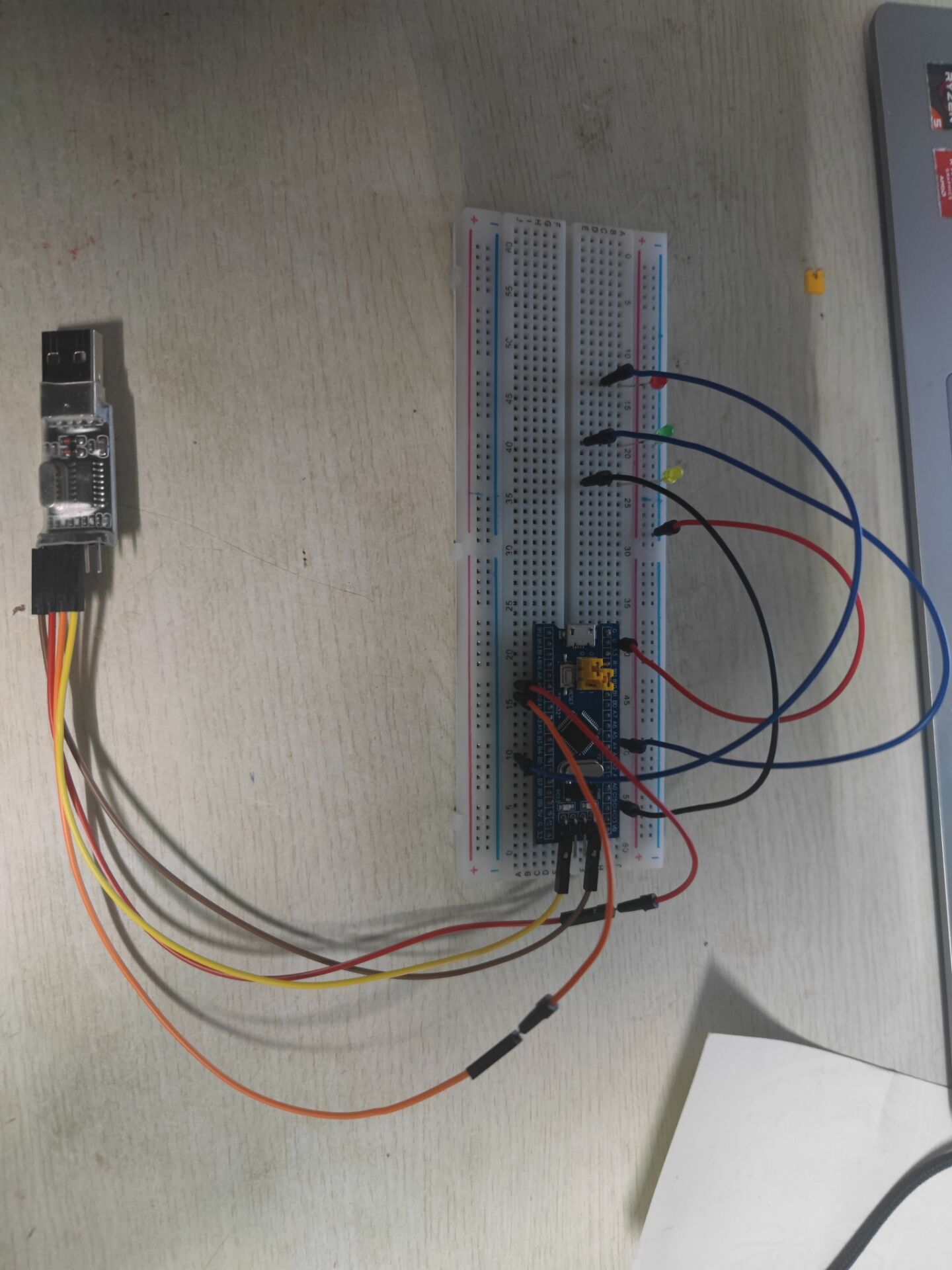

1) Connecting line

equipment

stm32 core board 103f

usb transfer interface

One red, yellow and green LED and several wires

Line connection

GND-G

3V3-3.3

RXD-A9

TXD-A10

Set B00T0 to 1, BOOT1 to 0, and press reset

GPIO and LED connections

A4 of GPIOA, B5 of GPIO and C14 of GPIO are connected to the positive poles of three LED lamps. Just connect three lights.

Connection diagram

2) Burn

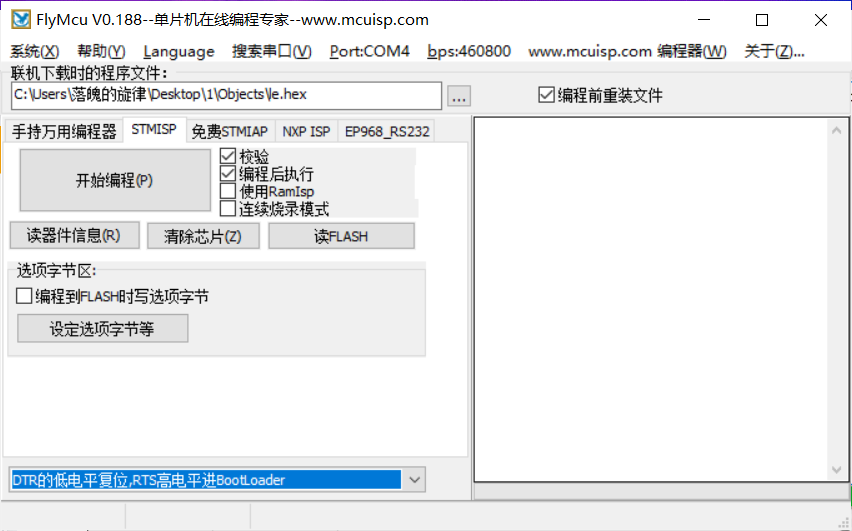

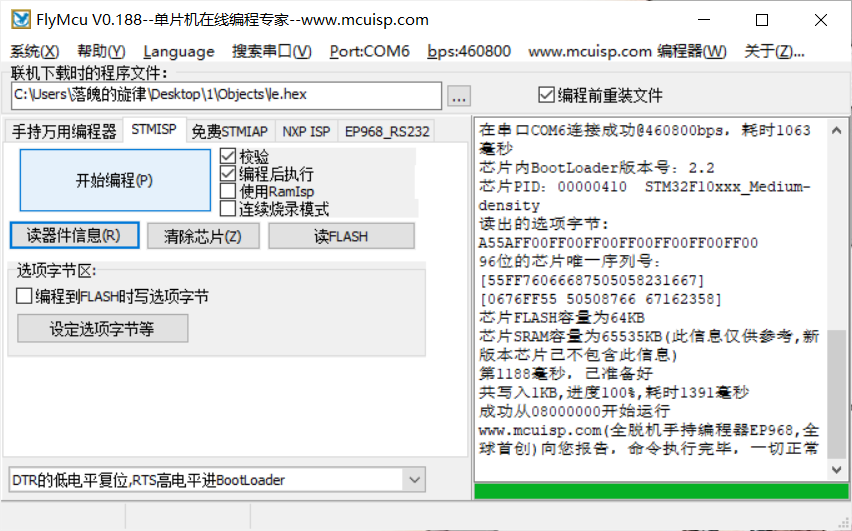

Insert the USB to TTL module into the computer, open mcuisp, click the search serial port, then upload the previously generated hex file, select the low level reset of DTR, and the high level of RTs into BootLoader

Click to read the device information and click to start programming. If successful, everything will appear on the right.

3) Water lamp effect

3, Summary

Through this experiment, I have a deeper understanding of STM32. At the same time, I learned to use it to light LED lights. Due to many difficulties encountered in the process of using STM32 for the first time, there are always errors in Keil compilation. In reality, Project cannot be generated. Only after consulting and knowing that it is a computer account and the user name is Chinese, baidu finally found a method. There was also a problem when connecting the board and it couldn't be burned. Finally, it was found that it was a connection error. After discovery, it was burned successfully, but finally, there was a problem with the light. After inspection, it was found that the problem was found. The board was in poor contact. Just press it a little.

4, References

https://blog.csdn.net/geek_monkey/article/details/86291377

https://blog.csdn.net/qq_60678931/article/details/120753360